Enology Notes #155

All past years' Enology Notes are still available. Use this link to jump to the most recent year's index: 2010 Enology Notes Listing.

Enology Notes #155, August 9th, 2010 - Link to PDF

To: Grape and Wine Producers

From: Bruce Zoecklein, Head, Enology-Grape Chemistry Group, Virginia Tech

Subjects:

- Planning and the 2010 Harvest

- Winery Water and Wastewater

- Winery Wastewater Treatment Systems

- Winery Wastewater Components

- Annual Flow Rate

- Cleaning Agents and Waste Minimization

- Wastewater Reuse

- Wine Marketing

1. Planning and the 2010 Harvest.

a. Science-Based vs. Empirical Knowledge

“Experience enables you to recognize a mistake when you make it again.”

– Bob Steinhauer-former Director of Vineyard Operations, Beringer Vineyards, CA

The kaleidoscope of viticultural and enological choices winegrowers must make reminds us of the complexity of our industry and how rapidly our philosophy and practices have changed as new knowledge is acquired.

To move forward, not laterally, from one vintage to the next, we need to keep Ray Koch’s famous remark in mind, perhaps with a slight modification: “You cannot manage (understand) if you cannot measure.” Our challenges, therefore, in crafting fine wines, include the understanding of the following:

- Environmental factors, vineyard management and fruit chemistry

- Fruit chemistry and wine chemistry

- Wine chemistry and sensory properties

To some, this mechanistic approach may appear to be contra natura, against their philosophical nature and against artistic winemaking. However, a resolution of the above relationships goes to a core belief – that luck is the residue of design. As John Fowles stated, “For what good science tries to eliminate, good art seeks to provoke – mystery, which is lethal to the one, and vital to the other.” However, art and science are supplementary. That understanding will allow us to follow an important mantra: keep things as simple as possible, but not simpler.

In order to optimally use both science and art, wemust understand the difference between empirical or observational knowledge, and science-based knowledge. We must know the limits and merits of each. Empirical knowledge is sometimes faulty, because what may apply to one circumstance may not to another. The question is one of relativism. What information is universal, and what information is specific to time, place and circumstance?

As an industry, the distinction between science-based and empirical knowledge is sometimes blurred. What works at one vineyard site certainly may not work at another. We know this intellectually, but sometimes fail to keep this in mind. Another problem with relying solely on empirical observations is that, if two outcomes are similar, we have a tendency to assume they must have a similar cause. This may or may not be correct.

One of the steps that can aid in understanding the relative merits empirical and science-based information is to develop a HACCP plan. HACCP is a system for assuring product quality control from beginning to end, through the identification and monitoring of the Critical Control Points (CCPs) during processing (see previous Enology Notes at www.vtwines.info).

HACCP plans integrate production (of both grapes and wines) with chemical, physical, microbiological, and sensorial analyses to help assure quality and style control. HACCP-like plans are designed to identify where CCPs occur, and establish control and monitoring measures.

Steps in Establishment of a HACCP Plan.

- Create a flow diagram from vine to glass.

- Identify the critical control point at each step in the process.

- Establish critical limits for each analysis to be conducted.

- Develop a monitoring procedure for each critical control point.

- Establish a plan for corrective action whenever critical limits are exceeded.

- Establish a record system to document action steps taken.

- Develop a verification plan for all analyses utilized.

Results must be regularly assessed to determine if additional steps or corrective steps are required.

A viticultural HACCP plan is important to help assure ultimate wine quality. It defines the grape production process, identifies the critical control points, measured values are compared with recommended values, and an action plan for correcting deficiencies is established.

b. HACCP Planning and Fruit Ripeness Indicators. The procedure outlined above can be important in maturity assessment as a function of the following. Each item has been outlined or discussed in previous editions of Enology Notes including #150 available at www.vtwines.info.

- use goal-driven maturity decisions

- maturity indicators should correlate to aroma/flavor and phenol suppleness

- fruit sampling methods are critical

- degree of asymmetric ripening in clusters and berries can have a profound influence

- sensory evaluation of skin, stem, pulp, and seed phenolic maturity

- chew skins, save reference samples from previous sampling dates to compare

- seed maturity (color, texture, and brittleness)

- seed numbers

- relationship between berry weight, shriveling, and engustment (rapid increase in free aroma/flavor volatiles)

- relationship between berry weight and physiological maturity

- berry softness and diffusion of pulp

- estimation of berry size

- sugar per berry vs. simple increases in Brix

- note that Brix and aroma/flavor, phenol development do not necessarily correlate

- changes in pH are not necessarily a function of berry ‘age’, but relate more to K+ and vigor

- Brix to alcohol conversion rate determines post-fermentation alcohol concentration and therefore palate balance

- TA (including tartaric/malic ratio) , pH, phenols (qualtive and quantitative ) and alcohol collectively impact wine structural/textural balance or mouthfeel

c. Planning for Red Wine Processing. Each item listed below should be carefully reviewed prior to harvest. Each has been outlined or discussed in previous editions of Enology Notes at www.vtwines.info.

Important red wine fermentation considerations and possible critical control points include:

- Brix to alcohol conversion rate/chaptalization

- alcohol and structural balance

- must TA, tartaric/malic ratio, pH adjustment

- berry size

- berry seed numbers

- fruit sorting, post-destemming sorting

- acceptable levels of rot, unripe berries, MOG, jack stems

- degree of berry breakage

- cold soak, duration and temperature

- enzymes

- fermentable nitrogen, adjustment, with what, when

- pre-fermentation tannin additions

- co-fermentations

- yeast(s) S. cerevisiae, S. bayanus, un inoculated

- yeast volume of viable inoculums

- sulfur dioxide

- role of oxygen/microoxygenation

- size and shape of fermentation tank

- open vs. closed fermentation tanks

- temperature of liquid and cap

- fermentation rate

- bleeding

- MLF, strain(s), timing, volume of inoculums

- punch down, pump over, irrigation systems, sweeper tanks, délestage, when, frequency

- alcohol at time of dejuicing

- post-fermentation maceration, anaerobic, duration

- free run vs. press run

- multiple press fractions

d. Several Red Wine Maceration Considerations: Cold Soak, Extended Maceration, Délestage. One overarching concern in red wine production is tannin management. Dr. Doug Adams of UC-Davis reported a study he and colleagues conducted on Pinot noir:

- Skin tannin concentrations of Pinot noir fruit differed by a factor of 6, depending on the growing region.

- Extractable seed tannin concentrations differed by a factor of 2.

- Wine tannin concentrations of commercial wines differed by a factor of 30.

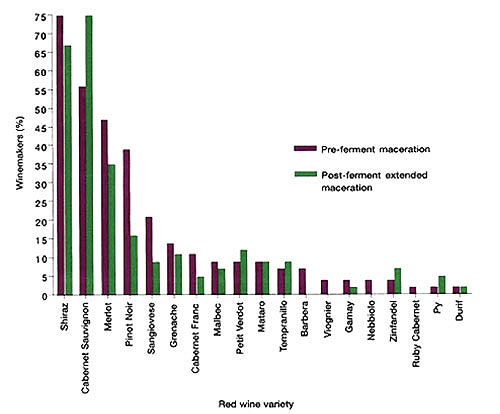

This highlights the variability of extraction of fruit tannins during processing. Two important red wine processing variables include cold soak and extended post-fermentation maceration (see the on-line publication: Tannins and Color, A Review previous editions of Enology Notes at www.vtwines.info). The following demonstrates the percentage of winemakers using pre- and post-fermentation maceration in Australia for selected varieties.

Figure 1. The percentage of Australian winemakers using pre-fermentation maceration and post-fermentation extended maceration (adapted from Crushing and Pressing: Research responds to determine extended maceration strategies for red wines. The Australian & New Zealand Grapegrower and Winemaker, June, 2008).

This highlights the interest in these two red wine processing steps among Australian producers.

Cold Soak. Cold soak may improve color, color stability and aromatic potential. A universal concern regarding cold soak is the possible increase in acetic acid and ethyl acetate as a result of biological activity durning the cold soak process. As I have discussed, the best way to minimize the potential problem (other than making sure the temperature is kept below 10° C) is to yeast. Adding wine yeast ( in the proper concentration, after proper hydration, followed by temperature reduction to minimize temperature shock) to the cold soak must provides some insurance. If the cold soak conditions allow for biological activity than an adequate concentration of wine yeast present will help insure that this activity is conducted mainly by desirable yeasts (low acetic acid producing).

For details regarding the nature of cold soak including the influences of cold soak duration see Enology Notes Index and On-Line Publications at www.vtwines.info).

Extended post-fermentation maceration. Extended post-fermentation maceration attributes reported include improved color stability and additional tannin structure and depth.

An important consideration is that fruit phenols, such as tannins, are relatively hydrophobic, a feature that limits solubility in the early stages of fermentation. As fermentation progresses, more tannin is extracted as the alcohol concentration increases.

Thus, during fermentation the medium changes from entirely aqueous (all water and, therefore, very polar) to partial alcohol with less water and less polarity. Tannins, being less polar than water, are more easily extracted as alcohol concentration increases. This may result in a quantitative and qualitative change and becomes very important when the phenolic elements of the fruit are not fully ‘mature’.

Délestage. The Effects of Délestage with Partial Seed Deportation on Merlot and Cabernet Sauvignon Wines (Zoecklein et al. 2007) is posted online (www.vtwines.info). This study compared délestage (rack and return) involving partial seed deportation, with Merlot produced by manual cap punching for three seasons, and Cabernet Sauvignon produced by mechanical punch-down (pigeage) systems for one season.

This on-line publication provides the full details of the study. General information regarding this production technique is available at www.vtwines.info. Click Enology Notes, then Enology Notes Index.

e. Pre-Harvest and Harvest YAN Analysis. Again this season Virginia Tech’s Enology Service Laboratory will conduct YAN and YAN component analyses for the industry.

- Email the Laboratory at Enology.Services@vt.edu to request processing bags and bottles

- Include name, company, mailing address, and the number of sampling kits required

- Collect juice samples at harvest, or grape berry samples from the vineyard pre-harvest*

- Fill sample bottles to the indicated level, mix thoroughly to dissolve preservative

- Ship samples overnight to the Laboratory; shipping delays impact analysis results

*Complete information regarding sampling and berry-bag processing can be found on the VT Enology-Grape Chemistry Group website (www.vtwines.info) under Online Publications > Maturity Evaluation for Growers.

The results are strongly dependent on adequate and representative sampling in the vineyard and proper sample processing.

Fermentable Nitrogen Analysis - $25

Ship samples to:

Wine/Enology-Grape Chemistry Group

Enology Service Lab

Attn: Ken Hurley

Rm. 113, FST Bldg.

Virginia Tech (0418)

Blacksburg, VA 24061

For more information on available analyses and analytical panels, please see the Enology-Grape Chemistry website at www.vtwines.info.

In some regions of the world, water seems a limitless commodity, while in other regions, it is just the opposite. As our industry continues to present itself as sustainably-oriented, we must continue efforts to understand how to wisely use this precious resource.

The word sustainable became common vernacular in the wine industry years ago. Never fully defined, it meant different things to different people, which was likely part of its initial appeal. It added a virtuous green dimension, which often represented some nebulous combination of ecology and the environment. For those in the wine industry, it usually meant some professed emphasis on energy, water, chemical, and/or packaging management.

For wineries to truly understand sustainable features, they need an energy/water/materials and chemical HACCP plan (see Enology Notes Index at www.vtwines.info). This plan must involve active audits, quantification and metrics. Without metrics, there is no way of knowing the true nature of the winery’s energy footprint, or the ability to compare one operation against another.

a. Water Use Auditing. Water limits are a crisis in California, and are expected to be exacerbated by global climate change. The state urban population consumes 21% of the water, while agriculture uses 79%. While a water crisis is looming in California, other regions of the country must also consider the use of this valuable resource. Regardless of the region, water has both an on-site and embedded energy cost that includes municipal water treatment, conveyance, pumping, etc.

It has been estimated that 16-20L of effluent may be generated for every ton of fruit crushed (Smith, 2002). Older wineries generate more water, with modern facilities generating 7-10L of wastewater per ton (Smith, 2009).

Any comparison of wine produced and water use must be made with an understanding of surface area and volume (Michael et al., 2009; Boulton, 2010). For example, a large winery will use water on a per surface area or liter basis, compared to a small winery, simply as a function of size, not necessarily operational efficiency. Only with scaling is it possible to compare one facility to another.

Currently, a significant effort is being undertaken to explore the principles and practices for water recovery and reuse, including clean in place (CIP), ‘green’ cleaning solutions, storage and solution recovery, reverse osmosis (RO) and nanofiltration, rain water harvesting, capture and reuse water systems, high pressure water, pigging transfer lines, etc. (Muhlack, 2008).

3. Winery Wastewater Treatment Systems.

Winery wastewater treatments vary from the simple and direct discharge into septic tanks, to more complex, capital-intensive systems, such as aeration ponds and aerobic digesters (Hamoudi-Viaud et al., 2004).

Winery process water management systems should have features of cost effectiveness, reliability, and ease of management and, optimally, should be reasonably compact. Controlling the amount and quality of process water results in realizing operational and capital savings, reducing water and chemical usage, and reducing the amount of organic solids going down the drain.

The industry is looking at wastewater treatment systems that will allow the elimination of high energy and land-intensive aeration ponds, and a reduction in the required storage volume. These have included wetlands. Aerobic systems are often characterized by (adapted from Szymanski et al., 2007). Next to simple discharge into septic systems, aerobic treatment systems are the most common.

- Wastewater evaporation ponds leading to ever-increasing storage requirements and limited land available for such purposes

- High salinity levels in the earthen evaporation basins

- Limited options for disposing of saline evaporite

- Odor

- Substantial freshwater use

- Substantial costs and energy usage

- Threats to the sustainability in taking effluent from the system

a. Aerobic Treatment Systems. A typical, traditional winery aerobic treatment system includes (Hamoudi-Viaud et al., 2004; Szymanski et al., 2007):

- Collection of wastewater in the winery, or its connection to a collective system

- Sedimentation for collected wastewater

- Screening of wastewater

- Transfer of wastewater into an aeration basin

- Sand filtration

- Monitoring of treated wastewater in a flow chamber before release into the environment

- Recovery and spreading of sludge

Modern improvements in wastewater systems have occurred. Some have involved new or improved systems, such as distillation (Pregler, 2009), and others simply operational changes, including:

- Stabilization of wastewater by basic pH manipulation

- Reducing or removal of sodium

- Improving water use efficiency in the winery

- Reuse of wastewater and maximizing nutrient removal through irrigation of cropland

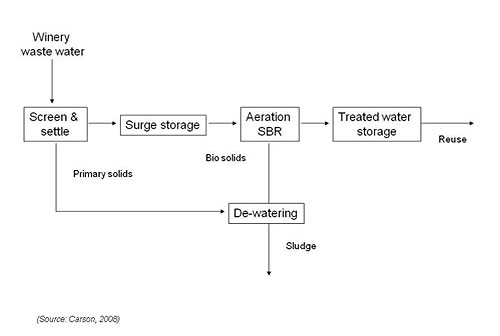

Figure 2. Waste water treatment system for a small winery.

b. Aerobic Digesters and Dissolved Air Flotation Systems (DAF). Dissolved air flotation systems are, or will become, a popular method of choice for treating winery wastewater. Such systems inject micron-size air bubbles into the flow from the bottom of a reaction vessel. Buoyancy lifts the air and materials, which are removed from the surface for disposal. Subsequently, the unit functions as a bio-digester (Johansen, 2003, 2004).

The system first screens the incoming influent (5-7 mm), followed by the removal of solids (TSS, total suspended solids), which reduces the load on the reactors. The “sludge” coming from a DAF unit goes into a series of aerated digester tanks.

DAF units contain materials (plastics, wood, etc.) to increase the surface area and therefore the bio-mass within the reactors, which allows for relatively small reactors. The final effluent leaving the system can range around 10-20 mg/L TSS. After the digestion period, the sludge can be used in composting operations. DAF units are currently available even for small (5,000 cs) wineries.

4. Winery Wastewater Components.

Winery wastewater contains inorganic salts, organic compounds, yeast and bacteria. The components that should be evaluated include the following (adapted from Kumar et al., 2008; Chouinard, 2009; Deans, 2003; Shepherd and Grismer, 1997):

- BOD5 (5-day biochemical oxygen demand): represents organic load, primarily of a soluble nature, consisting of alcohols and sugars. Domestic wastewater BOD is 200 mg/L on average; winery process water BOD is often about 7,700 mg/L; lees could have a BOD upwards of 100,000 mg/L

- COD (chemical oxygen demand)

- pH

- Total suspended solids (TSS)

- Total dissolved solids (TDS): Water with high TDS, and salt accumulation may, adversely affects crops, and takes away from other beneficial uses: some parts of the country regulatory agencies impose stringent TDS standards for effluent intended for land use

- Nitrogen

- Nitrate

- Phosphorous

- Sulfate

Pretreatment that most used to help optimize waste water treatment include the following (adapted from Szymanski et al., 2007; Smith, 2002):

- pH adjustment is required to create favorable conditions for biological treatment operations that follow pretreatment; currently, adding aqueous ammonia is common to adjust pH of winery process wastewater

- Sedimentation removes solids by allowing settling out of suspension; approximately 30 percent of BOD can be removed by a properly designed pretreatment system

The average winery loses 7% of product post-press (Goss, 2006). For every 100 liters of juice or wine that drains from the press, only 93 liters ends up on the customer’s table: the rest is lost down the drain (Goss, 2006).

Optimum process water management involves a reduction in water volumes and nutrient (wine) and salt loads in the wastewater.The higher the BOD level, the more product has been potentially lost in the process.

Potassium and nitrogen levels in wastewater are barometers of the source of the product loss. Generally, potassium in the waste water is from wine, nitrogen from the pomace. The higher the potassium in wastewater, the more wine and lees has been lost (Goss, 2006).

Estimated BOD, COD and physical and chemical values of winery wastewater (Chouinard, 2009):

Crush Season (mg/L)

Non-Crush Season (mg/L)

Reclaimed Water (mg/L)

BOD5

500 - 12000

300 - 3500

50

COD

800 – 1500

500 – 6000

90

pH

2.5 – 9.0

3.5 – 11.00

7.9

TSS

40 – 800

10 – 400

50

TDS

80 – 2900

80 – 2900

900

Nitrogen

1 – 40

1 – 40

5.0

Nitrates

0.5 – 4.8

---

1.5

Phosphorus

1 – 10

1 – 40

5.0

Sulfate

10 – 75

20 – 75

25

BOD load reduction means lower treatment processing costs. Every kg of BOD requires about 2 kWh of treatment energy. Five liters of lost wine means a one kW aerator needs to operate for around one hour to treat that wine loss (Goss, 2006).

Installing grates in the crush pad and pressing areas or at least directing rinse water to prevent ingress of skins, etc., can reduce the BOD demand, and salinity levels.

a. Winery Water and Waste Water Source Points. Water quality, monitoring and conservation require an understanding of point sources, where, and how water is used. Water sources and use areas include:

- Wells

- Wastewater ponds

- Septic systems

- Storm water

- Crushing

- Press

- Fermentation

- Barrel washing and soaking

- Cellaring

- Bottling

- Laboratory operations

- Landscaping operations

b. Typical Winery Sources of BOD (Adapted from Goss 2006).

Crush Pad:

- 3% of BOD load

- Average BOD of 50,000 mg/L

- While only a small load, the wastewater from pomace is difficult to treat

Fermentation and Pressing:

- 23% of BOD load

- Average BOD of 4,950 mg/L

Wet pomace can seep wine into drains and increase the BOD, salt loading, etc. Pomace that enters the drainage system carries product which could have been processed into wine. Wastewater rotary screens can help remove.

Tank Farm:

- 31% of BOD load

- Average BOD of 3,500 mg/L

Focus should be on recovery of product and reducing spillages and dumps of wine, particularly during transfers. According to some industry estimates, on average each liter of wine is moved as much as 10 times. This results in significant energy and water usage.

Pigging of major wine lines in and out of the tank areas can help reduce losses. Reuse of tank cleaning chemicals can reduce salinity and water volume, and should be considered by every winery, regardless of size. Clean in place (CIP) will be a common winery feature in the near future.

Barrels:

- 15% of BOD load

- Average BOD of 11,500 mg/L

The barrel cellar is an area of potential wine loss. Additionally, barrel lees have a very high BOD. Again, CIP and water recovery will become increasingly important.

Juice and Wine Clarification:

- 15% of BOD load

- Average BOD of 7,950 mg/L

Ideally, any area where DE is used should be isolated so that all DE can be collected. DE lost down the drain becomes a transfer medium for solids, etc into the wastewater.

5. Annual Flow Rates. Winery wastewater varies markedly in terms of its characteristics, particularly when comparing vintage and non-vintage periods. Typical monthly flow distribution as a percentage of annual flow (Chouinard, 2009):

Jan. 2.5% Feb. 2.5% Mar. 5.5% Apr. 9.0% May 8.5% Jun. 4.0% Jul. 4.0% Aug. 12.5% Sep. 18.5% Oct. 16.0% Nov. 12.0% Dec. 5.0%

A typical small winery (5,000 cases or 11,900 gal. annual production) could have the following gallons per day (GPD), according to Chouinard (2009):

Estimated annual water use up to 90,000 gal. Avg. daily flow 247 GPD Peak day flow (crush) 415 GPD Peak day flow (non-crush) 200 GPD

Seasonal changes are important, as are day-to-day changes. Variability in flow rates adds difficulty in designing biodigester-type wastewater treatment systems. As such, buffering storage (collection tanks) has several advantages:

- Can dampen the volumetric peaks and troughs, producing greater consistency in the quality of wastewater.

- Provides a more uniform and continuous stream for pH adjustments.

- Provides for some pre-settling for BOD reduction.

- Allows for easier segregation of particular waste streams, and only introduces each into the main wastewater stream very late in the treatment process.

- Possible control of odor production. Low pH values and high BOD and COD in wastewater favor the production of H2S. Raising the pH favors the production of its non-odorous disassociation product, HS-.

The net effect of these modifications is greater consistency in the volumetric flow rate and chemical and biological characteristics of wastewater.

6. Cleaning Agents and Waste Minimization.

In the past, the industry has been dependent on sodium-based products and caustic soda. Now, many are beginning to take a source-centric approach to winery wastewater management by understanding the mantra: recycle, reuse and reduce (Szymanski et al., 2007). Many are now using “green” cleaning materials and have replaced sodium with potassium products (Deans, 2003; Szymanski et al., 2007). Examples of the impact of potassium-based products on pH adjustment include (Boulton, 2010):

- Acid solution: 20mM KHSO4 provides pH 2.5

- Basic solution: 20mM KOH provides pH 11.5

The benefits of using potassium over sodium include:

- Potassium is a plant macro-nutrient, and preferentially taken up by crops in wastewater reuse areas, whereas sodium is not a plant nutrient. The very limited uptake of sodium is of an incidental nature only, and results in little net removal in harvested crops.

- Potential for soil degradation by K+ ions is dramatically reduced when compared to Na+ ions.

- While potassium hydroxide is more expensive than sodium hydroxide, any upfront cost disadvantage is more than offset by the lower mitigation and remediation costs associated with addressing impacts on soil in wastewater utilization areas.

In the past, the cleaning agents and processes in wineries were heavily dependent upon the use of sodium-based products and, in particular, caustic soda.

Treatment systems have focused on removing organic matter, nitrogen, and phosphorus but, generally, they are incapable of removing sodium. Through replacement of sodium products with potassium products, we have re-engineered the chemistry of the wastewater so that its relative content of calcium and potassium (both plant macro nutrients) has increased with a reduction in sodium (Carson, 2008).

In November of 2009, The Enology-Grape Chemistry Group of Virginia Tech in conujunction with Surry Community College in North Carolina conducted a highly successful meeting titled, “Winery Tasting Room Design and On-Site Marketing.” This meeting highlighted another aspect of sustainability, how to sustain your business in this economic downturn. We had a number of marketing and design experts, including Paul Wagner, President of Balzac Communications & Marketing. Paul is an internationally recognized wine marketing expert. The following are excerpts from his presentations.

a. Five Great Tactics for Marketing – Paul Wagner. Each will lead towards success. These are not mutually exclusive—do them all!

#5: Listen. Stop talking and listen. Every current customer is a source of new business and new customers. But you have to listen to them to learn from them. “Propaganda ends where dialogue begins.” – Marshall McCluhan

#4: Tell a good story. Customers want to fall in love. Keep it short and to the point. What is your story?

#3: Try five good ideas. See which ones work, and expand them. Which ones need work? Improve them. Which ones don’t work? Forget them. Add 2-3 new ideas a year.

#2: Create community around your brand. Make your customers part of your team. Trust them. Give them the chance to make a difference in your company.

#1: Spend two hours every day doing marketing and sales. As a small winery, you only have time and money. Invest them both wisely—especially your time!

What is Success? Success is NOT making great wine! It is making wine and selling it at a great profit. That is sustainable. Every day, you need to find ten more customers. Or 20. Or 200. That is success.

b. The 6 Biggest Mistakes: Recipes for Long-Term Disaster – Paul Wagner. How many of the following describe your marketing?

#6: We just need one big idea that will solve all of our marketing problems. There is no such thing as the silver bullet. Marketing is hard work, and you need to invest time and energy into developing different ways to reach the market.

#5: I can do this myself cheaper. No you can’t. You can’t do some of this stuff. You don’t know how to do some of it. And you don’t have time to do the rest.

#4: My wine is so good it will sell itself. No, it’s not. And it won’t. If you think it is, then put it on a shelf in a local supermarket and see how fast it flies out the door.

#3: I can hire a top professional and not have to think about this. Good idea—bad execution. Top professional marketers know a lot, and can do a lot—but they can’t help you without a LOT of your time and attention.

#2: I’ll get a 90+ rating and sit back and watch the money roll in. Sorry, but hundreds of wines get 90+ points each year. Yes, such a score will help your sales team and give you credibility…but if you get a lower score next year, you will lose all of that.

#1: I don’t have time to do marketing — I am too busy growing grapes and making wine. You don’t have time to run your business, you are too busy playing with it.

References

Carson, M. 2008. Wastewater treatment for small and medium wineries. Nov.:61-64.

Chouinard, J.A. 2009. Verbal communication.

Deans, L. 2003. Winery wastewater – scourge or opportunity? Wine Ind. J. 18:80-85.

Goss, P. 2006. Cleaner production: it’s easier than you think. Australian Society of Viticulture and Oenology Proceedings: Maximizing the Value – Maximize Returns Through Quality and Process Efficiency. 12 Oct. 2006:34-35.

Hamoudi-Viaud, M.-N., F. ois Berthoumieux, and A. Descotes. 2004. Traditional winery waste water techniques. Internet J. Vitic. Enol. www.infowine.com.

Johansen, T. 2004. Evans & Tate adopt a benchmark waste treatment technology. Aust. NZ Grapegrower Winemaker 481:38-40.

Johansen, T. 2003. Buying a wastewater treatment digester. Aust. NZ Grapegrower Winemaker 477:53-56.

Kumar, A., R. Correll, and R. Kookana. 2008. Winery wastewater workshops translate research into practice. Wine Ind. J. 23(6):60-63.

Michael, P., D. Oemcke, and N. Scrimgeour. 2009. Benchmarking winery production: developing benchmarks. Aust. NZ Grapegrower Winemaker 545a:66-69.

Muhlack, R. 2008. Necessity, the mother of invention: being smarter with energy and water. Wine Ind. J. 23(6):58-59.

Pregler, B. 2009. Improved distillation for winery wastewater. Wine Bus. Monthly April:94-96.

Shepherd, H.L., and M.E. Grismer. 1997. Constructed wetlands: an alternative for treating winery wastewater. Vineyard Winery Mgmt. Sep/Oct:65-67, 78.

Smith, F. 2002. Winery waste water options. Aust. NZ Grapegrower Winemaker April:40-41.

Szymanski, N., S. Lott, L. Gullifer, P. Binns, and R. Glastonbury. 2007. Re-engineering of waste management systems at De Bortoli Winery, Bilbul, NSW. Aust. NZ Grapegrower Winemaker Aug.:65-69.

All past years’ Enology Notes are still available. Use this link to jump to the most recent year's index: 2010 Enology Notes Listing.![]()

Subscription to Enology Notes. All past Enology Notes newsjournals are posted on the Enology-Grape Chemistry Group's web site at: http://www.vtwines.info/.

To be added to (or removed from) the Enology Notes listserve send an email message to with the word "ADD" or "REMOVE" in the subject line.

Dr. Bruce

Zoecklein

Professor and Enology Specialist Head Enology-Grape Chemistry Group

Department of Food Science and Technology, Virginia Tech

Blacksburg VA 24061

Enology-Grape Chemistry Group Web address: http://www.vtwines.info/

Phone: (540) 231-5325

Fax: (540) 231-9293

Cell phone: 540-998-9025

Email: