Enology Notes #150

All past years' Enology Notes are still available. Use this link to jump to the most recent year's index: 2009 Enology Notes Listing.

Enology Notes #150, August 27th, 2009 - Link to PDF

To: Grape and Wine Producers

From: Bruce Zoecklein, Head, Enology-Grape Chemistry Group, Virginia Tech

Subject:

- France Technical Study Tour

- Winery Tasting Room Design and On-Site Marketing Meeting

- Fruit Ripening

- Use of Electronic Nose as a Vineyard Monitoring Tool

- Winery Sustainability Program Online

- The Enology Service Laboratory Yeast Assimilable Nitrogen (YAN) Measurements

1. France Technical Study Tour. The 2009 Wine Industry Technical Study Tour is an 8-day tour of Southern France to meet and interact with key grape growers, winemakers, and technical support personnel. The dates are December 1 – December 9, 2009.

The objectives:

This is a unique opportunity to visit and participate in technical discussions on a wide variety of practical grape and wine production topics. This Study Tour is designed for personnel in the commercial grape and wine industry, and includes:

- Visit the flagship wineries and vineyards in Southern Rhône, Provence, and Languedoc.

- Visit the three leading institutions for practical grape growing and winemaking: Institut Coopératif du Vin (the largest wine consulting company in the world), InterRhône (the Rhône research and experiment center), and Centre du Rosé (the experiment center for Provence wines).

- Visit the largest equipment show for vineyards and wineries in the world: SITEVI (Salon International des Techniques et Equipement Viti-Vinicoles).

- A unique opportunity to meet and exchange ideas with top wine growers of Rhône varieties, in some of the best and most unique places (Muscatà Petits Grains at Lunel, Grenache at Gigondas, Mourvèdre at Bandol, Clairette at Palette).

- A unique culinary opportunity for fine food and fine wines.

This 2009 Technical Study Tour will be led by:

Pascal Durand, Professor, University of Burgundy, and Director of the International Marketing postgraduate program of SupAgro Dijon, Dijon, France.

Bruce Zoecklein, Professor of Enology, and Head of the Enology–Grape Chemistry Group at Virginia Tech, Blacksburg, VA.

Keith Patterson, Professor of Viticulture, CalPoly, San Luis Obispo, CA.

This study tour is restricted to wine industry professionals only. For additional details, including the full itinerary, go to www.vtwines.info.

2. Winery Tasting Room Design and On-Site Marketing. A program on winery tasting design and on-site marketing is scheduled at Surry Community College, Dobson, North Carolina, on Saturday, November 14, 2009.

Organized by Dr. Bruce Zoecklein, Head, Enology-Grape Chemistry Group, Virginia Tech, and hosted by Surry Community College, this one-day program will bring some of the country’s leading marketers and winery tasting room designers together to discuss and highlight the relationships between design components and wine marketing.

The program includes sensory evaluations, and sessions on sensory training of your tasting room staff.

The program will include the following topics:

- Sensory Exercises to Train Tasting Room Staff

- Winery Tasting Room Design

- Strategies for On-Site Marketing

- Common Winery Marketing Mistakes

- Winery Sustainability and Branding

- ‘Designing’ Your Tasting Room Staff

- Optimizing Winery Tourism

- Winery Business Planning and Cash Flow

Speakers include:

Craig Root, Craig Root & Associates, Napa, CA. Craig has designed a number of Napa Valley winery tasting rooms.

Paul Wagner, Balzac Communications and Marketing, Napa, CA. Paul is an author and leading wine marketing consultant.

Barbara Lindblom, Winemaker Consultant and Sensory Specialist, Santa Rosa, CA.

Patty Held, Patty Held Consulting Services, Herman, MO. Patty has 25 years’ experience in wine marketing, including tasting room staff training.

Jerry White, Agricultural Economist and Professor Emeritus, Cornell University. Jerry has an extensive background in winery economics and has aided many producers on issues of evaluating cash flow and marketing.

Annette Boyd, Director of the Virginia Wine Board Marketing Office, Richmond, VA, and President of Ringwood Boyd Marketing.

Note: This program involves sensory evaluations. Therefore, space is limited.

Registration cost is $150. Registration form available at www.surry.edu (see Events and Announcements on homepage).

3. Fruit Ripening. The relatively high moisture we have experienced in many vineyards in the region has added to yet another unique season. A significant volume of research has advanced our understanding of how various viticultural variables and practices, including fruit maturity, crop level, crop exposure (Bergqvist et al., 2001; Zoecklein et al., 1998), leaf area to crop ratio (Kliewer and Dokoozlian, 2005), shoot density, and training systems (Reynolds et al., 1996) affect grape composition and maturation.

Our research on grape glycosides (in part, aroma/flavor precursors) has suggested that greater wine quality proceeds from fruit that reaches its targeted maturity earlier vs. later (see On-line Publication titled Effect of Crop Load on Grape Aroma/Flavor at www.vtwines.info).

Vines with fruit with delayed maturity are either out of balance, young, or are poorly managed with respect to cropping level, irrigation/soil moisture, pruning and/or canopy management. Important features also include:

- Fruit temperature

- Humidity

- Rainfall

- Site characteristics, including soil type and sun exposure

- Soil moisture, irrigation management, deficit irrigation

- Variety/clone

- Training and trellising systems

- Row orientation

- Canopy management

- Rootstock

- Yield components: kg fruit/vine, clusters per vine, clusters per shoot, berries per cluster, berry weight

One continuing concern is the large degree of asynchronous ripening in some vineyards. A number of studies have reviewed the factors impacting vineyard variation (Rankine et al., 1962; Smart and Robinson, 1991; Trought, 1996; Trought and Tannock, 1996). Variation is an inherent part of biological systems. Variation in the vineyard occurs among berries, bunches, and vines. Vineyard variability may be increased this season due to environmental conditions.

A crop with asynchronous clusters or berries has a mixture of developmental stages, resulting in berries with optimal qualities diluted by berries which may be inferior. A juice with Brix of 22° might be composed of a narrow distribution of a few berries at 20° and a few at 24°Brix, with the majority nearer to 22°. However, there may be a much wider distribution, with berries below 18° and greater than 24°. Because °Brix is a distribution average, juices with similar °Brix values can produce quite different wines, due to variations in aroma/flavor and phenolic compounds.

Two components of berry-to-berry variation are significant in grape and wine production: size and berry composition. In extreme cases, this is referred to as ‘hen and chicken’ or millerandage (Winkler, 1965). Variation in berry size affects vineyard yield and, perhaps, wine quality. High levels of variation in the early post-flowering period suggest that variation originated prior to berry set. Such variation most likely results from asynchronous cell division at budburst. Decreasing levels of variation may indicate points of re-synchronization in the berry growth cycle: the more synchronized the event, the lower the variation (Gray, 2006).

Variability of visually uniform vines (below), expressed as percentage of the coefficient of variation, was reported by Gray (2006), indicating the inherent nature of vineyard variability. While soluble solids concentrations may be fairly uniform, with a coefficient of variation usually less than ten per cent, the variance can be much greater if the fruit is not uniform across the clusters, or if the cluster microenvironment is variable among vines:

- Brix 4 to 5%

- pH 3 to 4%

- Titratable acidity 10 to 12%

- Berry weight 6 to 20%

- Color 13 to 18%

Many variables can be measured at the vine level, including soil characteristics, node number, shoot number, cluster number, and vine position, etc.

Spatial analysis techniques and global positioning systems (GPS) have aided our understanding of vineyard variability. Aerial vineyard images, using satellite or aircraft, can be used to calculate a normalized different vegetation index (NDVI) for each vine. These maps can be used to visualize differences in vine vigor or relative biomass on a vineyard scale (Hall et al., 2002). This is a common practice in California.

Since yield forecasting and maturity testing procedures may rely on cluster sampling, differences in cluster size can be a major source of error. Stratified cluster and berry sampling programs have been devised to overcome some of these problems (see On-line Publication titled Maturity Evaluation for Growers at www.vtwines.info), but seasonal, varietal, and site-specific considerations still confound any general sampling protocol (Wolpert and Howell, 1984; Kasimatis and Vilas, 1985). The variables that contribute to variation among bunches include inflorescence primordia size, flower number, fruit set, berry number, cluster weight and, notably, cluster position.

Variation among berries is poorly understood. A typical berry follows a double-sigmoid growth curve during its post-flowering development, but two berries in the same cluster may follow quite different paths (Matthews et al., 1987). The divergence of the growth curves becomes apparent shortly after flowering, and the timing of this divergence is responsible for the extent of the difference between the two berries at harvest. Uneven berry development and its impact on wine quality is largely undocumented.

The variables that contribute to variation between berries include berry size, berry composition, seed number, seed size, and berry position. Factors that may contribute include variations in cluster architecture, the role of vascular function in berry growth and development, the relationship between seed development and berry development, and the relative importance of cell division and cell expansion (Gray, 2006).

e. Measuring vineyard variation.

It is difficult for growers to easily quantify the extent of cluster or berry variation. It is possible to compare the results of five 100-berry samples and, with some simple calculations, quantify the degree of variation.

For example, expressed as a percentage, the coefficient of variation (CV) is a unitless measure of the sample variability, relative to the sample mean. Comparison of CVs can reveal the extent of variation:

coefficient of variation (CV) = |

standard deviation (s) |

× 100 |

mean ( |

f. Vineyard variation management.

Zonal management and zonal harvest are appropriate techniques for helping to manage vineyard variability. While after the fact, perhaps the best approach to help minimize vine variation is site selection. Variation may be minimized by choosing a site with limited variation in soil, topography, aspect, and extreme weather events.

Evaluation and quantification of vineyard variation has been a justification for our efforts using electronic nose technologies (see below).

4. Research Update: Use of Electronic Nose as a Vineyard Monitoring Tool. As reported in previous editions of Enology Notes, we have been evaluating various electronic nose systems for their application in the grape and wine industry. The following is an abstract from work conducted by Yamuna Devarajan, an MS student in the Enology-Grape Chemistry Group at Virginia Tech.

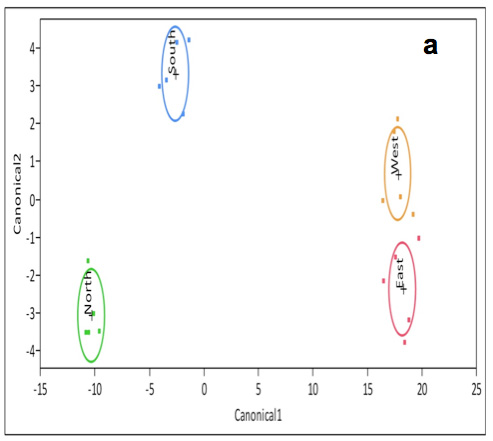

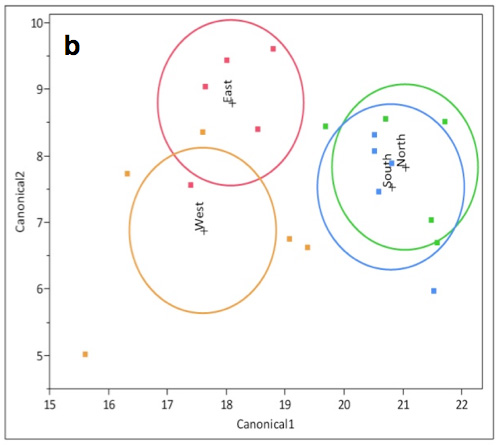

The effect of canopy side on grape and wine volatiles of Cabernet franc was evaluated using two electronic nose systems (conducting polymer-based and surface acoustic wave-based) during two growing seasons. Fruit from three sampling dates each season, from North-South and East-West facing vine rows, was evaluated by both electronic nose systems and compared with physico-chemistry: berry weight, Brix, TA, pH, color, total glycosides, and phenolic-free glycosides. Wines were produced from fruit from each side the canopy, and wine aroma sensory evaluations and analysis of wine volatile compounds were compared with electronic nose analyses.

Statistical analyses generally indicated grape physico-chemistry indices were not able to differentiate between canopy sides (East vs. West or North vs. South) consistently across growing seasons and sampling dates. Wine aroma sensory evaluation was also not able to consistently differentiate canopy sides.

However, both the electronic nose systems provided 100% discrimination of canopy sides for grapes, and for wines produced from those grapes. The evaluation by one of the electronic nose systems is non-destructive and requires only 40 seconds. As such, we believe that this emerging technology may be a valuable vineyard management tool.

|

| A. Canonical plots of electronic nose data for Cabernet franc fruit |

|

| B. Canonical plots of physico-chemical data for Cabernet franc fruit |

The canonical plots represent the multivariate mean of the data points as circles, whose size indicates 95% confidence limit for the mean. Non-intersecting circles indicate significant differences. As can be seen, canonical plots of the electronic nose data (A), measuring fruit volatiles, show that the instruments consistently differentiate canopy sides. The canonical plots for the physico-chemistry data (B) illustrate that these indices could not differentiate between sides of the canopy. More to follow.

5. Winery Sustainability Program Online. A Winery Sustainability and Design program that I organized, covering many winery sustainability issues, is available online. The subjects of this Adobe Presenter program (audio and slide presentations) are as follows:

- Sustainability in Winery Design

- Sustainable Winery Architecture

- Why Solar, Why Now

- Gravity Flow Design, Principles and Practices

- Cellars, Caves and Earth-Sheltered Design

- Winery Construction and Sustainable Building Materials

For more information, go to www.vtwines.info. See "Winery Sustainability Program Online".

As suggested by Dr. Roger Boulton (UC Davis), as an industry, we need to properly quantify our ecological and environmental sustainability activities. Without quantification, we may be guilty of simply contributing to the cascade of ‘green washing’.

The advantages of quantification and benchmarking lie in our ability to measure and compare. A number of matrices can and should be reviewed, including a few examples provided by Michael et al. (2009):

- Wine volume/ton

- Total energy/ton

- Water/volume of wine produced

- Wastewater COD and BOD/ton

Some of these features are evaluated and discussed in the upcoming Edition 16 of the Winery Planning and Design CD available September 1, 2009 from Practical Winery and Vineyard magazine. Details are available at www.vtwine.info.

6. The Enology Service Laboratory Yeast Assimilable Nitrogen (YAN) Measurements. The Enology Service Laboratory is again offering pre-harvest and harvest yeast assimilable nitrogen analysis for the 2009 season. We measure YAN, NH3 and Arginine. The sample submission procedure is posted online and outlined in Enology Notes #149, available at www.vtwines.info.

References

Bergqvist J, Dokoozlian N and Ebisuda N (2001), ‘Sunlight exposure and temperature effects on berry growth and composition of Cabernet Sauvignon and Grenache in the Central San Joaquin Valley of California’, Am J Enol Vitic, 52, 1-7.

Gray J (2006), ‘The basis of variation in the size and composition of Shiraz berries’, in Oag D, DeGaris K, Partridge S, Dundon C, Francis M, Johnstone R and Hamilton R, 'Finishing the Job' - Optimal Ripening of Cabernet Sauvignon and Shiraz, Adelaide, SA, Australian Society of Viticulture and Oenology, 30-35.

Hall A, Lamb D W, Holzapfel B and Louis J, (2002), ?Optical remote sensing applications in viticulture - a review’, Austral J Grape Wine Res, 8, 36-47.

Kasimatis A N and Vilas E P, (1985), ‘Sampling for degrees Brix in vineyard plots’, Amer J Enol Vitic, 36, 207-213.

Kliewer W M and Dokoozlian N K (2005), ‘Leaf area/crop weight ratios of grapevines: influence on fruit composition and wine quality’, Am J Enol Vitic, 56, 170-181.

Matthews M A, Cheng G and Weinbaum S A, (1987), ‘Changes in water potential and dermal extensibility during grape berry development’, J Amer Soc Horticult Sci, 112, 314-319.

Reynolds, AG, Wardle DA, Naylor AP. (1996), Impact of training system, vine spacing, and basal leaf removal on Riesling vine performance, berry composition, canopy microclimate, and vineyard labor requirements, Am. J. Enol. Vitic., 47, 63-76.

Smart R and Robinson M, (1991), Sunlight into Wine: A Handbook for Winegrape Canopy Management, Winetitles, Adelaide.

Trought M C T, (1996), ‘Sources of variation in fruit composition in New Zealand vineyards’, in Stockley C S, Sas A N, Johnstone R S and Lee T H, Proceedings 9th Australian Wine Industry Technical Conference, Adelaide, Australia, Winetitles, Adelaide, 206-207.

Trought M C T and Tannock S J C, (1996), ‘Berry size and soluble solids variation within a bunch of grapes’, Henick-Kling T, Wolf T E and Harkness E M, Proceedings 4th International Symposium on Cool Climate Viticulture and Enology, Rochester, New York, New York State Agricultural Experiment Station, Geneva, NY, V-70-73.

Winkler A J (1965), General Viticulture, Berkeley, California, University of California Press.

Wolpert J A and Howell G S, (1984), ‘Sampling Vidal Blanc grapes. II. Sampling for precise estimates of soluble solids and titratable acidity of juice’, Amer J Enol Vitic, 35, 242-246.

Zoecklein B W, Wolf T K, Duncan S E, Marcy J E and Yasinski Y W (1998), ‘Effect of fruit zone leaf removal on total glycoconjugates and conjugate fraction concentration of Riesling and Chardonnay (Vitis vinifera L.) grapes’, Am J Enol Vitic, 49, 259-265.

![]()

Subscription to Enology Notes. All past Enology Notes newsjournals are posted on the Enology-Grape Chemistry Group's web site at: http://www.vtwines.info/.

To be added to (or removed from) the Enology Notes listserve send an email message to with the word "ADD" or "REMOVE" in the subject line.

Dr. Bruce

Zoecklein

Professor and Enology Specialist Head Enology-Grape Chemistry Group

Department of Food Science and Technology, Virginia Tech

Blacksburg VA 24061

Enology-Grape Chemistry Group Web address: http://www.vtwines.info/

Phone: (540) 231-5325

Fax: (540) 231-9293

Cell phone: 540-998-9025

Email: