Enology Notes #141

Enology Notes #141, May 30, 2008 - Link to PDF

To: Winemakers and Perspective Winemakers

From: Bruce Zoecklein, Head, Enology-Grape Chemistry Group, Virginia Tech

Subjects Discussed in Enology Notes #141:

- Sustainable Winery Expansion

- Conducting an Energy and Water Use Audit

- BEST-Winery Spreadsheet Program

- Sustainable Winery Expansion Considerations

- Fermentable Nitrogen, A Review of the 2007 Season

- New On-Line Publications:

- Oxidation Sensory Screen

- Hydrogen Sulfide/Mercaptan Sensory Screen

1. Sustainable Winery Expansion.

At our Sustainable Winery Layout and Design Seminar, architect Joe Chauncey of Boxwood Architects, Seattle WA, listed the following attributes common to a sustainable winery:

- Ecologically responsable

- Economically viable

- Good neighbors

- Bioregional

- Healthy and sensible

- Operationally efficient

- Aesthetically pleasing

Our industry is becoming more aware of resource limitations. Building and construction in the USA uses 65% of the electricity consumed, produces 30% of the greenhouse gas emissions, uses 30% of the raw materials, and consumes 12% of the potable water. A study conducted in California several years ago reported the wine industry was the largest energy user among food industries. This realization, coupled with concerns regarding global climate change, has promoted continued interest in sustainability.

The long-term operational savings from sustainable winery designs and expansions may help to offset some of the initial costs. Additionally, sustainability can be important in brand identification. ‘Green’ construction involves the integration of the site, design, and construction, including the sustainability of the site, water usage, energy usage, environmental quality, and materials. In considering a sustainable winery expansion, the following steps should be followed:

1st: Conduct an energy and water use audit.

2nd: Create an integrated energy and water management plan.

3rd: Begin by initiating the simple changes such as converting to energy efficient

lighting, minimal exterior lighting, cut off fixtures, motion sensors, and/or timers

for both interior and exterior lighting.

Conduct an energy and water use audit. General sources of energy consumption in the winery (from A Guide to Energy Efficiency Innovation in Australian Wineries) include:

- Refrigeration: 40-60%

- Pumps, fans, drives: 10-35%

- Lighting: 8-20%

- Compressed air: 3-10%

- Packaging and bottling: 8-30%

- Other consumptions: 3-15%

Before expansion, mapping the whole winemaking process correctly and understanding water and energy use can save energy and money. Energy efficiency depends on many factors, including:

- Proper sizing of equipment for winery capacity

- Building design and orientation

- Building insulation

- Type of refrigeration system

- Refrigeration line insulation

- Tank type(s) and insulation

- Water usage, water recovery efficiency, and hot water line insulation

- Type of lighting, layout, and night-lighting used

- Utilities use and sources

- Electrical

- Water

- Sewage

- Ventilation

- Air conditioning

- Heating

- Refrigeration

There are several on-line programs available that help integrate these features into water and energy use plans.

BEST-Winery. BEST-Winery is a free spreadsheet-based software tool designed to evaluate the energy and water efficiency for still wine production. This program created by Christina Galitsky and Ernst Worrell of the Lawrence Berkeley National Laboratory is an excellent tool to assess environmental and financial impacts of current operations and suggests potential improvements.

BEST-Winery calculates an energy intensity index and water intensity index, with both indicators compared to established benchmarks. The software program incorporates information about winery-specific process steps and characteristics, such as those listed above, affecting energy and water use and volumes. The program allows the user to evaluate opportunities for energy and water efficiency improvement, to assess the impact on the performance of the facility, and to appraise operation costs. This can help develop an implementation plan for energy and water efficiency improvement for both a current facility and an expansion.

BEST-Winery Guidebook: Benchmarking and Energy and Water Savings Tool for the Wine Industry prepared by Lawrence Berkeley National Laboratory (Christina Galitsky, Ernst Worrell and Antony Radspieler) and Fetzer Vineyards (Patrick Healy and Susanne Zechiel) contains detailed discussions on understanding and estimating the potential for annual energy savings (both for electricity and fuel), energy costs savings, carbon dioxide (CO2) emission reduction, water, and water cost savings if the winery performs at the same performance level as a benchmark standard. The program evaluates the following areas:

- Water efficiency

- Refrigeration

- Pumps

- Compressed air

- Motors

- Lighting

- Hot water and heat supply

- Other fuels

- Other electric

- Cogeneration

BEST-Winery has been designed for California producers but has application to others. To view this program go to http://best-winery.lbl.gov.

Begin by initiating the simple changes. At the Sustainable Winery Layout and Design meeting in March 2008, a number of presenters outlined simple strategies of sustainable winery construction and expansion (see below). More detailed information on these topics is available in the Winery Planning and Design CD, Edition 14. For information regarding the CD, go to www.vtwines.info, click Winery Planning and Design.

Sustainable winery expansion considerations. The following sustainable winery considerations, adapted in part from Chauncey (2006 and 2008), should be carefully evaluated in both the initial and winery expansion phases.

- Use cool-build materials:

- If metal roofs are utilized, use materials developed or painted with infrared reflecting pigments to lower the amount of heat-absorbing light. This can create a cool roof.

- Cool roofs reduce heat absorption and cooling costs.

- Reduce heat loss or gain:

- Have portions of buildings underground or partially underground to take advantage of the earth’s constant temperature.

- Have barrel storage areas where walls are in contact with the earth, which can eliminate the need for cooling. Air movement from fan coil units cooling an above-ground barrel room dries out the barrels and increases evaporation. To help control this problem, winemakers humidify this space, adding cost and some additional potential problems.

- Barrel rooms that do not need cooling will promote less evaporation.

- Consider geothermal heating and cooling:

- Water circulates in a sealed loop that extends well into the earth.

- In the winter, the water absorbs heat from the earth and carries it to a compressor which raises the temperature.

- In the summer, the water takes heat away form the building and transfers it to the earth.

- Use regional materials and local fabricators:

- This helps to reduce transportation impacts and stimulates the local economy. See Enology Notes #140 for a listing of imbedded energy of building materials.

- Use building and construction materials with a high percentage of recycled

content:

- Straw construction buildings are becoming more popular. Straw is the inedible stock of grains such as wheat, rice and rye.

- Orient buildings to take advantage of solar energy or maximize shading.

- Optimize the use of shading:

- Blocking sunlight that would fall on building surfaces can dramatically reduce cooling loads such as bris soleil (slotted wall) systems.

- Plant trees along the south and west faces of the buildings.

- Install wall trellises, grow vines or shrubs to shade walls.

- Design sunscreens that shade and ventilate heat away from the wall surfaces.

Example of a bris soleil reducing the solar heat interception.

Source: Chauncey 2008

- Consider low emissivity insulation on windows:

- Metal oxide glazing can allow the sun’s heat and light to pass through glass while blocking the heat from leaving the building, thus reducing heat loss.

- Use bris soleil (slotted wall) to reduce direct sunlight into windows:

- Slotted wall perpendicular to the window can defuse direct sunlight and reduce heat interception.

Source: Chauncey 2008

- Increase daylight levels and outside views:

- Add skylights or upper windows (clerestories), while avoiding direct sunlight on barrels or tanks.

- Design additional windows and skylights in subterranean spaces to expand views to the outdoors from as many occupied spaces as possible.

Source: Chauncey 2008

- Design natural ventilation:

- Design windows or louvers at or near the floor level of the winery to bring in cool night air that blankets the ground. By also opening a louver in the upper part of the winery, a passive ventilation system is created. Hot air that has been accumulated during the day can be exhausted through a louver in the clerestory area. The hot air leaving the winery pulls cool night air in the lower louver. Such purging can be done without mechanical equipment.

- Water usage:

- Reduce water use by collecting wash-down waters: Settle/filter the water, adjust the pH, and use for irrigation of winery grounds.

- Consider rainwater collection systems for landscape irrigation, etc.

- Sustainable site planning:

- Use native and adaptive plants, and landscape that will require minimum irrigation and helps to promote biodiversity.

- Use minimal exterior lighting and computerized cut off fixtures, motion

sensors, and/or timers for both interior and exterior lighting:

- Use environmentally sound lighting.

- Create a building with mass:

- A thin-walled building with a metal skin and batt insulation allows heat (and cold) to penetrate more quickly than a thick-walled building.

- Build with concrete, masonry, or stone, and sandwiched insulation.

- Thick-walled buildings absorb heat all day long, and release it at night with little impact on the interior temperature.

- Consider solar:

- Many wineries have installed photovoltaic panels to provide some or all of their electrical needs.

- Use solar water pumping.

- Establish a recycling program.

Sustainability means development today which does not rob future generations from doing their own development.

2. Fermentable Nitrogen, a Review of the 2007 Season.

Nitrogen (N) is a limiting nutrient in grape must that impacts yeast growth, the capacity to ferment, and the production of sensorially important metabolites that impact wine quality.

It has been established that simple blanket additions of N-containing nutrients, such as DAP, to musts can dramatically change wine quality and styles. As such, an understanding of the N concentration in the fruit pre-fermentation, vineyard factors impacting the concentration, and optimum winery management strategies are essential for premium wine production.

As has been outlined in previous editions of Enology Notes (available at www.vtwines.info, Click Enology Notes Index), the nitrogen required by yeast to conduct a healthy fermentation includes two forms: ammonia N, and a group of amino acids referred to as alpha-amino acids, or free amino nitrogen (FAN). Together, these sources contribute the nitrogen utilized by yeast, referred to as yeast-assimilable nitrogen (YAN). There is a correlation between low concentrations of YAN and SLO (sulfur-like off odor) formation.

Ken Hurley, Director of The Enology Service Laboratory at Virginia Tech conducted an extensive analytical survey of 235 juice samples during the 2007 harvest season, evaluating the total yeast assimible nitrogen (YAN), ammonia, and arginine concentrations. The following highlights some of these results.

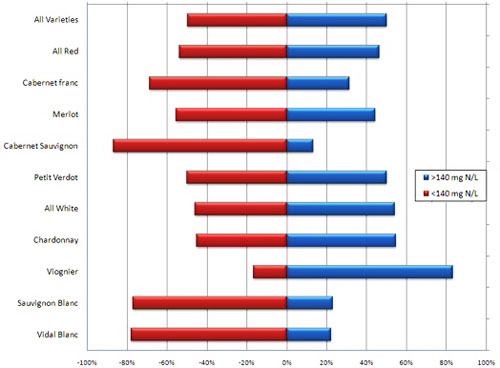

Figure 1

Figure 1 shows the concentration of YAN found in all red and white varieties at harvest, expressed as a percentage above or below 140 mg/L YAN. The minimum level considered to be optimum for fermentation management if no other limiting factors are present is about 140 mg/L. It should be noted that the 2007 season was warmer and dryer than most and that these data represent only one year.

A number of viticultural and environmental factors can impact fruit YAN. These may include:

- Cultivar

- Soil

- Soil moisture

- Rot incidence

- Vineyard fertilizations, including mulch

- Crop load

- Climate, season

- Maturity

From véraison onward, the following changes occur in the fruit:

- NH4+ increases, then declines

- FAN amino acids increase, then decline, with the rate of decline different among FAN components

- With extended maturity, YAN declines

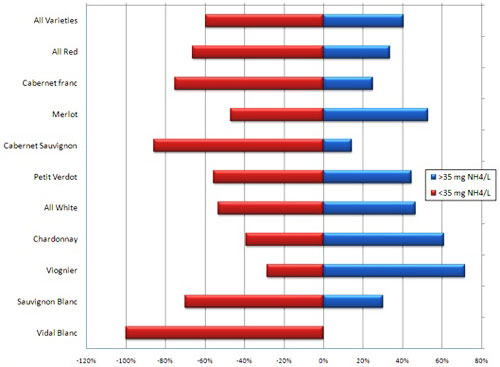

Figure 2

Figure 2 shows the relative concentration of NH4+ found in red and white varieties. These data are expressed as a percentage greater than or less than the overall average value which was 35 mg/L NH4+.

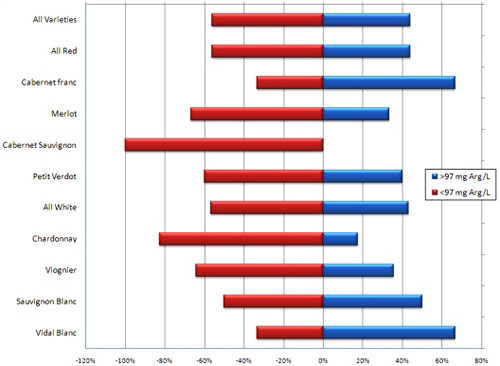

Figure 3

Figure 3 shows the relative concentration of arginine in fruit expressed as a percentage greater than or less than the average concentration.

FAN amino acids increase, then decline in the fruit, with the rate of decline different among FAN components. Arginine is the most abundant FAN amino acid. As such, it is thought to be a very important source of yeast nitrogen. It accumulates before veraison and continues to maturity, then generally declines. Commonly, the greater the ‘hang time’ the lower the arginine concentration. There is a negative correlation between Brix and arginine level.

Studies on the impact of nitrogen application in the vineyard on overall grape quality have provided conflicting results, due in part, to the confounding issues of variety, rootstock, soil, soil moisture, and climate.

However, vineyard nitrogen application can increase the concentration of the major nitrogenous compounds, including FAN amino acids, ammonium, and thus overall fruit YAN. As such, nitrogen application is used to manipulate grape YAN, to a degree, but it is understood that adjustments may be needed at the winery.

An important question remains unresolved: Does the source of YAN nitrogen (native, produced in the fruit vs. supplement addition to the must) impact wine quality? It seems intuitive the answer to this question could be yes, given the compositional differences between native YAN and commercial supplements.

Vineyard nitrogen application should be considered only when factors such as vine vigor, canopy density, leaf color, petiole nitrogen, and possibly fruit YAN, indicate the need.

It has been suggested that YAN be used to help evaluate the need for subsequent vineyard fertilization. Fruit YAN composition may be a better barometer of the nitrogen status than the overall plant (petiole) composition.

At low nitrogen sites, increases in fruit YAN can usually be achieved by applications of inorganic or organic nitrogen fertilizers. Maintenance of adequate nitrogen status at moderate nitrogen sites can be achieved in the same way, but nitrogen application should be avoided at sites that are high in nitrogen. High YAN concentrations in the fruit can cause problems (see below).

Winemakers aim to achieve an adequate concentration of juice YAN that will help to secure healthy fermentations. As suggested, that level is usually 140 mg/L or more, depending on other variables such as sugar concentration, yeast strain, and micronutrient status.

Grape growers and/or winemakers should test fruit for the YAN concentration at harvest or slightly pre-harvest. This provides the winemaker with important information needed to help produce a premium wine.

Must nitrogen is an important consideration impacting wine style. While it seems counterintuitive, too much YAN can be as detrimental as too little. In the past many winemakers did not evaluate fruit or must YAN status, but assumed a deficiency and simply added N. Too frequently this resulted in an excess of YAN. High must YAN results in some common features:

- Increased yeast biomass

- Increased heat produced during fermentation

- Possible increased formation of ethyl acetate, acetic acid, and volatile acidity

- May increase the concentration of ethyl carbamate and biogenic amines such as histamine

- Increased risk of microbial instability

- Potential taint from Botrytis-infected fruit

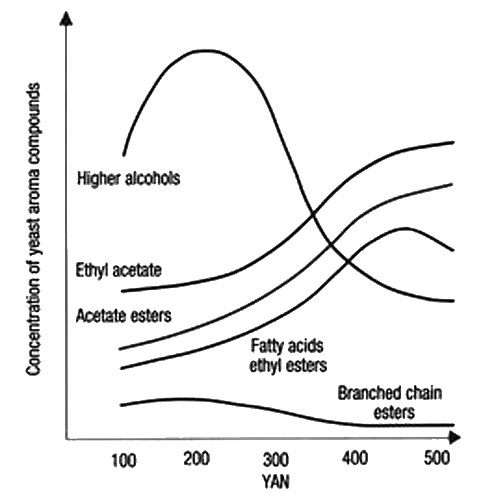

Figure 4

Source: Ugliano et al. 2007

Figure 4 illustrates the various volatile groups found in wine impacted by YAN. While this shows the trends observed, it should be noted that the figure does not represent quantitative relationships among different chemical classes. Additions of DAP or proprietary supplements without an understanding of the must YAN concentration can result in excess YAN, producing a wine of very different, and possibly less preferred quality and style.

Low must YAN results in some common features:

- Reduced yeast populations

- Reduced fermentation vigor

- Increased risk of slow or sluggish/stuck fermentations

- Increased potential for SLO

- Decreased production of esters and long chain fatty acids

Nitrogen application in the vineyard can be used to manipulate the must YAN, but fine tuning is often done in the winery by the use of nitrogen supplements.

Information on the timing and addition rate of DAP to must before and during fermentation has been improved, but consequences for overall quality are still to be determined. Additionally, it seems logical that nitrogen management for red wine fermentations may differ from white wines.

Optimization of vineyard and fermentation nitrogen management can contribute to wine quality and stylistic features and hence affect its commercial value.

Two new publications have been posted on-line: Oxidation Sensory Screen (Oxidized Aroma Screen: Acetaldehyde) and Hydrogen Sulfide and Mercaptan Sensory Screen. Both simple lab procedures are adapted from Zoecklein et al. (1999) and posted at www.vtwines.info. Click On-Line Publications.

![]()

Subscription to Enology Notes. All past Enology Notes newsjournals are posted on the Enology-Grape Chemistry Group's web site at: http://www.vtwines.info/.

To be added to (or removed from) the Enology Notes listserve send an email message to with the word "ADD" or "REMOVE" in the subject line.

Dr. Bruce

Zoecklein

Professor and Enology Specialist Head Enology-Grape Chemistry Group

Department of Food Science and Technology, Virginia Tech

Blacksburg VA 24061

Enology-Grape Chemistry Group Web address: http://www.vtwines.info/

Phone: (540) 231-5325

Fax: (540) 231-9293

Cell phone: 540-998-9025

Email: