Enology Notes #140

Enology Notes #140, April 22, 2008 - Link to PDF

To: Winemakers and Perspective Winemakers

From: Bruce Zoecklein, Head, Enology-Grape Chemistry Group, Virginia Tech

Subjects Discussed in Enology Notes #140:

2. Sustainable Winery Layout and Design, Meeting Review

3. Winery Planning and Design CD, Edition 14 Available

1. Electronic Nose Research Update, Continued: Effects of Clusters per Shoot and Cold Soak on Grape and Wine Volatiles. The following is a review of a vineyard project nested in a study on cold soak. Some cold soak issues were discussed in Enology Notes #139. This work was conducted by a MS candidate in the Enology-Grape Chemistry Group, Denise Gardner.

The purpose of this research was to evaluate electronic nose systems to 1) determine the effect of cluster numbers/shoot on grape and wine volatiles, and 2) determine effect of cold soak on grape and wine volatiles.

Merlot (Vitis vinifera) grapes were cluster thinned to either 1 cluster per shoot or 1 and 2 clusters per shoot at véraison. Fruit was harvested from the central Virginia vineyard on Sept. 16, 2007.

Differences in primary fruit chemistry at harvest between the two vineyard treatments were generally not observed. The 1 cluster/shoot vines averaged 22.5 degrees Brix, while the 1 and 2 clusters per shoot treatment averaged 22.8 degrees Brix. Differences in pH were noted, an average of 3.97 vs. 4.14 for the 1 vs. 1 and 2 cluster per shoot treatments, respectively.

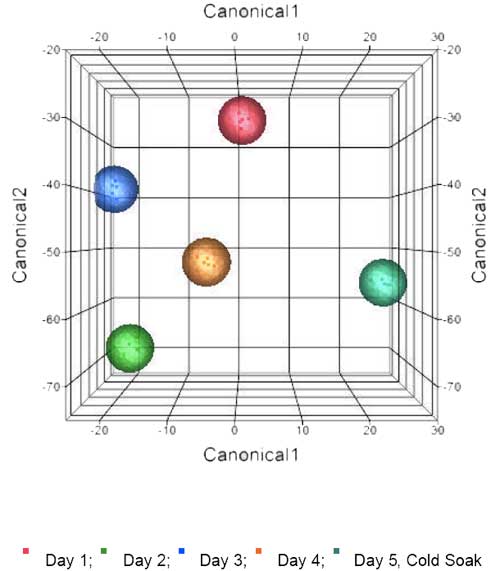

Measurements of fruit volatiles were conducted at harvest. Figure 1 demonstrates the pattern of volatiles generated using a conducting polymer-based electronic nose system. As demonstrated by Figure 1, fruit was clearly separated based upon vineyard treatment suggesting an impact of treatment on grape volatiles.

Figure 1: Canonical Distribution of Merlot Berries at Harvest

(Blue= 1 and 2 Cluster/Shoot, Red= 1 Cluster/Shoot)

Grapes were crushed and separated into fermentation bins of equal weights based on vineyard treatment, and additional treatment variables imposed including: 1 vs. 6 days cold soak. Each bin was treated with DMDC (Velcorin,TM Scott Labs) to help assure that biotic activity did not impacted the study.

The 1-day cold soak bins were held at 4-7°C for 24 hours then warmed and inoculated with Saccharomyces cerevisiae . Fermentation was monitored daily and caps were punched 3 times a day. At dryness, the wine was pressed and the free run and press run wines kept separately. After 24 hours, the wine was racked.

Cold soaked bins were held at 4-7°C for 6 days, and then inoculated. Fermentation, pressing, and racking were the same as for the 1-day cold soak treatment.

Each bin was sampled daily for electronic nose analysis. Five replications were conducted per treatment.

Figure 2 demonstrates the changes noted in total volatiles during 5 of 6 day cold soak days for the 1 cluster per shoot treatment. Volatiles show distinct separation based on day sampled.

Figure 2: Changes in Juice Aroma of Cold Soak 1-Cluster/Shoot

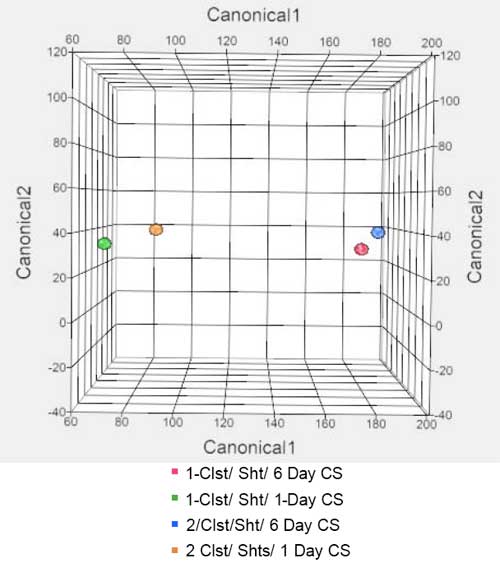

Figure 3 (below) shows the distribution of volatiles of all wines immediately post-fermentation. A grouping of 1 day cold soak wines compared with 6-day cold soak wines was observed. Based on wine volatile components, there was a greater similarity between the both 6 day cold soak treatments compared to the 1 day cold soak wines. The degree of variation in volatiles of the two cold soak treatments is likely due to the vineyard treatment.

Figure 3: Canonical Distribution of All Wines Immediately Post-Fermentation

GC-MS analysis and other electronic nose evaluations are in progress which will continue to characterize aroma differences.

More to follow. For additional information on the Enology-Grape Chemistry Group’s electronic nose research go to www.vtwines.info. Click Enology Notes or On-Line Publications.

2. Sustainable Winery Layout and Design, Meeting Review. A highly successful meeting on Sustainable Winery Layout and Design was conducted in March in association with Wineries Unlimited 2008. This day-long program brought together experts from around the country to discuss sustainable issues. The topics included the following:

- Building a Sustainable Winery: Principles and Applications

- Sustainable Winery Architecture, LEEDS

- Winery Energy Options, Solar

- Creative Options in Integration of Winery Equipment and Design

- Sustainable Building Materials

- Gravity Flow Design: Principles and Practices

- Cellars, Caves and Earth-Sheltered Design

- Tasting Room Design Considerations

- Winery Design Case Studies

We are currently planning additional meetings to be held on the west coast on these and other sustainable topics.

Some of the information presented in March is available in Winery Planning and Design, Edition 14. Ordering information is available at www.vtwines.info. Click Winery Planning and Design.

In a presentation given at our Sustainable Winery Layout and Design meeting titled Sustainable Winery Architecture, Joe Chauncey from Boxwood Architecture, Seattle WA, provided some interesting and important insights regarding sustainability. The following are adapted from his excellent presentation.

What is a sustainable winery? Most would agree that they include the following attributes:

- Ecologically responsive

- Economically viable

- Good neighbors

- Bioregional

- Healthy and sensible

- Operationally efficient

- Aesthetically pleasing

Joe Chauncey went on to characterize the nature of some sustainability issues. In America buildings are responsible for:

- 12% of the potable water use

- 30% of the greenhouse gas emissions

- 65% of the total electrical consumption

- 136 M tons per year of construction and demolition waste

Joe defined the term embodied energy, which is the total energy required to produce and use building materials in kilowatt hours/ton. The total embodied energy of selected materials is as follows:

- Wood 640

- Masonry 2,560

- Concrete 3,200

- Plastics 3,840

- Glass 8,960

- Steel 15,360

- Aluminum 80,640

These kilowatt hours/ton do not reflect such confounding issues as life of the materials, strength, maintenance or the possible use of recycled materials. Regardless, the dichotomy in the energy required to make and transport building materials is dramatic. Also included at the meeting on Sustainable Winery Layout and Design were discussions of the impact of day-lit vs. artificially-lit buildings. The difference in energy consumption is striking:

- Artificially-lit buildings: 1.5 Watts/SF

- Day-lit buildings: 0.33-0.5 Watts/SF

3. Winery Planning and Design CD, Edition 14 Available. The information from Joe Chauncey’s presentation (see above) and others is included in Winery Planning and Design, Edition 14. Ordering information is available at www.vtwines.info. Click Winery Planning and Design.

4. New On-Line Publications. Several new publications have been added to those posted on-line at www.vtwines.info. Click On-Line Publications to review the following:

- Current Theory and Application of Micro-oxygenation

- Electronic Nose Evaluation of Grape Maturity

- The Electronic Nose Knows

- Grape and Wine Color and Tannins

- Viognier, Effect of Training System on Fruit and Wine Quality

5. Virginia Tech Wine Weekend . Virginia Tech is hosting the Virginia Vintner’s Table at Virginia Tech: Presenting our Best Harvests weekend on May 23-25, 2008 on the Virginia Tech campus in Blacksburg, Virginia.

The purpose of the event is to showcase wines being produced in Virginia. This will be a weekend featuring the most outstanding wineries within the state of Virginia and their wines, which have competed in and won awards on the national and international levels. Information is available at www.alumni.vt.edu/vavintnerstable.

6. In Remembrance. The tragedy at Virginia Tech occurred about one year ago. The following is a quote I shared shortly afterwards.

“The mindless menace of violence in America…again stains our land and every one of our lives. It is not the concern of any one race. The victims of violence are black and white, rich and poor, young and old, famous and unknown. They are, most important of all, human beings whom other human beings loved and needed.

“No one – no matter where he lives or what he does – can be certain who will suffer from some senseless acts of bloodshed. And yet it goes on and on in this country of ours. Why? What has violence ever accomplished? What has it ever created?”

“Yet we seemingly tolerate a rising level of violence that ignores our common humanity and our claims to civilization alike… This much is clear: violence breeds violence… and only a cleansing of our whole society can remove this sickness from our soul.”

“We cannot vanquish violence with a program, nor with a resolution. But we can perhaps remember, if only for a time, that those who live with us are our brothers, that they share with us the same short moment of life; that they seek, as do we, nothing but the chance to live out their lives in purpose…happiness [and] satisfaction…Surely this bond of common faith, this bond of common goals, can begin to teach us something.”

Robert F Kennedy.

![]()

Subscription to Enology Notes. All past Enology Notes newsjournals are posted on the Enology-Grape Chemistry Group's web site at: http://www.vtwines.info/.

To be added to (or removed from) the Enology Notes listserve send an email message to with the word "ADD" or "REMOVE" in the subject line.

Dr. Bruce

Zoecklein

Professor and Enology Specialist Head Enology-Grape Chemistry Group

Department of Food Science and Technology, Virginia Tech

Blacksburg VA 24061

Enology-Grape Chemistry Group Web address: http://www.vtwines.info/

Phone: (540) 231-5325

Fax: (540) 231-9293

Cell phone: 540-998-9025

Email: