Enology Notes #139

Enology Notes #139, March 5, 2008 - Link to PDF

To: Regional Wine Producers

From: Bruce Zoecklein, Head, Enology-Grape Chemistry Group, Virginia Tech

Subjects Discussed in Enology Notes #139:

1. The Oregon Wine Industry Research and Extension Funding Plan, Chill Cells, Cold Soaking

2. Use of an Electronic Nose for Maturity Evaluation, continued

3. Management of Sulfur-Like Off Odors in Wine, a HACCP Plan

1. The Oregon Wine Industry Research and Extension Funding Plan. I was fortunate to have par ticipated in the Oregon Wine Industry Symposium, held in Eugene, this February. Following the very well organized and well attended symposium, I traveled through the Willamette Valley visiting a number of wine producers.

Sunlight and heat are often in short supply, making ripening a challenge in Oregon. Weather patterns can be somewhat erratic from year to year, which can make for some significant vintage variations. Despite inherent environmental limitations, the industry has grown and is thriving.

The success of the Oregon wine industry is not simply due to overall quality of wines like Pinot noir and Pinot Gris, in my opinion, but to the progressive attitudes of industry members. In this era of diminishing public support for agricultural research and extension, the Oregon industry has developed a plan to create an Oregon State University Wine Institute. This is a partnership between the industry and OSU for the overall purpose of expanding the economic potential of the Oregon industry. The Institute will focus on viticulture, enology, and wine business, both extension and research. As of the start of the 2008 Oregon Wine Symposium, 18 wineries had pledged $20,000 each for the creation of the Wine Institute!

In this country, public funds to conduct grape and wine research are very limited, and declining. As recently suggested by Dr. Roger Boulton, UC-Davis, “Matching the Australian industry’s level of funding would just allow us to remain 10 years behind.”

Regional wine industries would be well advised to consider the OSU Wine Institute model, or some alternative, if they desire to see extension and research efforts maintained or expanded to help secure their economic future!

Chill Cells. Several Oregon wineries I visited had elaborate chill cells or built-in refrigeration chambers to chill fruit. In one winery, Pinot noir was stored up to 45 hours in their cold cells which had a very significant forced airflow. Such storage was reported to have several advantages, including allowing for a regulated processing flow and workload, increasing the fruit Brix, and aiding in processing. Fruit stored had Brix increases of 0.3 to 0.5 degrees, likely the result of removing surface water coming in from rainy vintages (last year in Oregon was a particularly wet harvest season). An additional advantage was that cold Pinot noir allows for easier, more gentle de-stemming with fewer broken berries, thus lowering the non-soluble solids level going into the fermentor.

Cold Soak. An important initial processing question is the desirability of cold soak, or prefermentation maceration. It appears that the majority of Oregon Pinot noir producers cold soak, some for an extended period of up to 30 days. The rationale behind cold soak is that aqueous extraction in a non-alcoholic matrix improves wine color and color stability, and may increase aromatic intensity. Is that true? Sometimes, yes, but not always.

Monomeric anthocyanins are extracted during cold soaking, which may result in increased finished red wine color. Tannin extraction during cold soak is limited by solubility. Tannins are extracted at a slightly lower rate than anthocyanins, but the extraction continues throughout the maceration period. Seed tannin extraction requires ethanol. Therefore, tannins extracted during cold soak are from the skins and stems, not the seeds.

Important cold soak variables include the following:

- varietal

- season

- time

- temperature

Some varietals may actually have less red wine color following cold soak. Highly-colored varieties, like Cabernet Sauvignon, frequently demonstrate an increase in color absorbance at 520 nm as a result of cold soak, but this increase may not persist through wine aging. The impact of cold soak on various varietals needs further review.

Large variations, mainly in cofactor concentration (see Enology Notes #116), may be responsible for both varietal and seasonal variations on the impact of cold soak.

Most winemakers practicing cold soak use a temperature low enough to limit the growth of unwanted microorganisms, such as Kloeckera. As such, a temperature below 10°C is considered desirable.

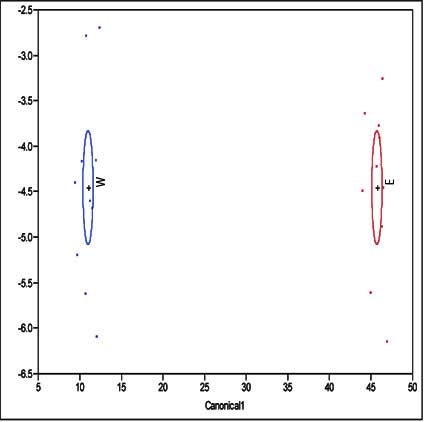

A student in the Enology-Grape Chemistry Group examined the impact of cold soak time on Cabernet Sauvignon wine chemistry, seven months post-fermentation (Figures 1 and 2). NS indicates not significant, * indicates significance at 0.05.

Figures 1 and 2

Red-colored pigments have a maximum absorption at 520 nm. Brown pigments have a maximum absorption at 420 nm. Color intensity (520 nm + 420 nm) actually decreased with increased cold soaking time. Color hue, defined as the ratio of absorbance at these two wavelengths, went up, likely due to the increased relative concentration of tannins, which contribute to brown color.

Practical effects of cold soak are a function of time and cultivar. There may be little benefit from more than three days soaking. The impact of cold soak on wine aroma has not been fully resolved. More on this subject to follow.

2. Practical Applications of the Electronic Nose in the Vineyard.

Denise Gardner, Masters Candidate, Enology-Grape Chemistry Group, Virginia Tech.

Denise recently received the College of Agriculture and Life Sciences Outstanding MS Graduate Student Award. The following is an excerpt from her presentation given at the 2008 Virginia Vineyards Association meeting.

The electronic nose is an analytical tool that the Enology-Grape Chemistry Group has been evaluating for several years. Previous research has shown that a hand-held conducting polymer-type electronic nose can non-destructively distinguish volatile aroma differences in grapevine clusters of differing maturities.

In support of this research, a study was conducted on Cabernet Franc grapes grown with two different row orientations: East/West and North/South. Electronic nose readings were collected once a week for five weeks prior to harvest, on the same set of clusters. Additionally, clusters were harvested and analyzed under controlled conditions for the following traditional maturity indices: weight per berry, pH, TA, Brix, color (hue and intensity), aroma and flavor precursors, sugar per berry, and total phenols. These analyses were compared individually and as a group with the electronic nose readings.

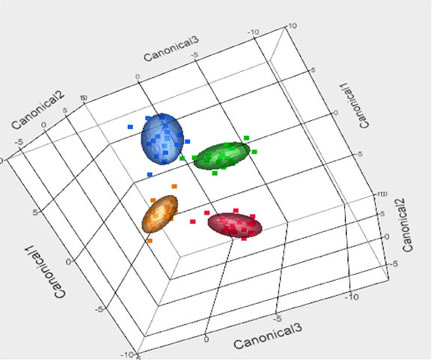

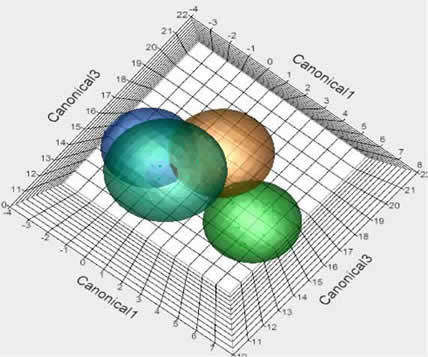

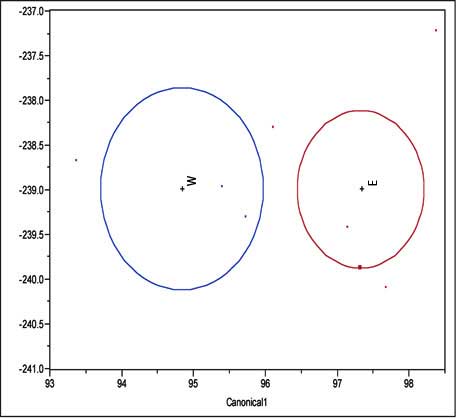

It was found that the electronic nose could distinguish volatile aroma maturity progression and differences better than the traditional chemical and physical indicators, for both row orientations, from the beginning of the study through harvest (Figure 3).

Using canonical distribution, separation of volatile aroma profiles using the electronic nose was greater than the separation provided by the physicochemical analyses.

Figure 3. Canonical distribution of ENose (left) and physicochemical indices (right) in monitoring maturity over four weeks. Note the overlapping and great dispersion in the physicochemical data, which consists of 10 traditional maturity indices.

The electronic nose measurements could detect differences in the volatile profile from different sides of the grapevine canopy (East vs. West and North vs. South), while the physicochemical analyses showed little difference and only slight separation, as indicated below. Comparison of the electronic nose with conventional GC/MS analysis is in progress.

Figure 4. Canonical distributions of ENose (left) and physicochemical indices (right) in canopy side differences (W = west, E = east). Note the greater degree of separation and tighter clustering of the ENose results.

Studies conducted by the Enology-Grape Chemistry Group have shown that the use of this emerging technology may be of practical importance to the grape and wine industry. The ENose used in the above evaluations is a simple, hand-held device able to measure fruit volatiles non-destructively in 45 seconds. In our analyses, electronic noses were consistently able to provide greater separation of fruit maturity levels in considerably shorter time periods than required by traditional indexes.

Of importance, electronic noses analyze grape aroma components developed through engustment, the rapid increase in free aroma volatiles that is correlated to wine varietal character.

Current research by members of the Enology-Grape Chemistry Group is evaluating a number of applications of this technology with various types of electronic noses, and includes vineyard and winery applications.

3. Management of Sulfur-Like Off Odors in Wine, a HACCP Plan

The following is adapted from a presentation I gave at the Oregon Wine Industry Symposium.

“Genius is like fleet of foot, method is the right path.

Fleetness of foot on the wrong path never leads to knowledge.”

–Francis Bacon

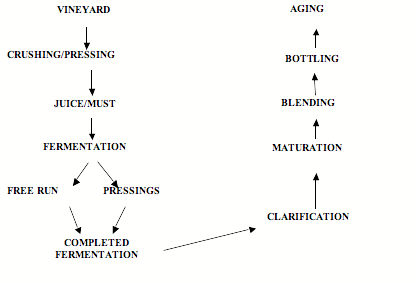

HACCP stands for hazard analysis and critical control points. Originally designed as an aid to minimize the incidences of food-borne illness, HACCP is one tier in a general quality management program. The use of a systemized, standard methodology such as HACCP can aid grape growers and winemakers in assuring consistent quality and the ability to reach stylistic goals.

HACCP can help to answer several universal, philosophical, yet practical questions. What data is certain and why? Is one way of gathering facts about the world (including your vineyard and/or wine) more dependable than others?

One problem with simple observation is that if two outcomes are similar, we tend to believe they have similar causes, which is not always the case. HACCP allows for an understanding of the relationships between cause and effect in the complex world of viticultural and enological decision making. The seven steps of a HACCP plan are listed below.

The Seven Steps of a HACCP Plan.

- Create a flow diagram from vine to glass.

- Identify the critical control points at each step in the process.

- Establish critical limits for each analysis to be conducted.

- Develop a monitoring procedure for each critical control point.

- Establish a plan for corrective action whenever critical limits are exceeded.

- Establish a record system to document action steps taken.

- Develop a verification plan for all analyses utilized.

Step 1.

Step 1 involves creating a flow diagram or outline from vine to glass. This outline can be general or very detailed, depending on the degree of specification desired. HACCP allows growers and winemakers to customize a quality management system tailored entirely to specific needs and their own production practices and philosophy.

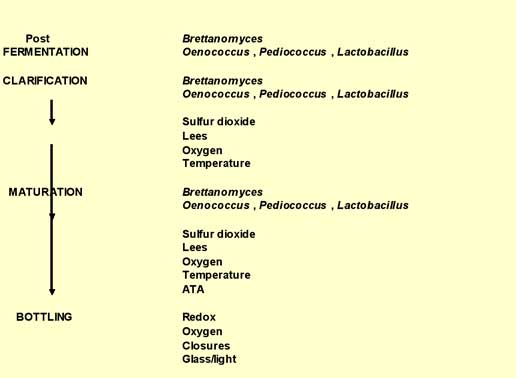

Figure 5.

Step 2.

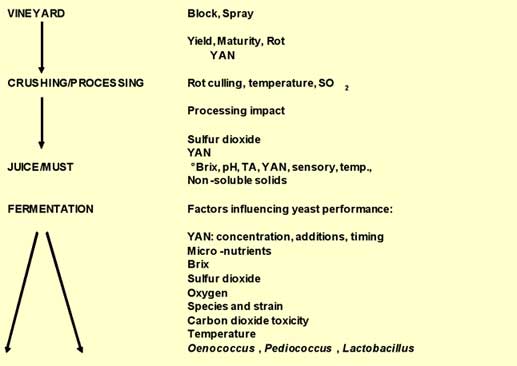

Step 2 of a HACCP plan involves the identification of critical control points (CCPs) within the outline created in Step 1. The CCPs are any points or features in the production scheme that are believed to impact quality and/or stylistic goals.

The basic premise behind development of CCPs is fundamental. Newton, in inventing the calculus, took advantage of the principles of Descartes: when a problem seems large and complex, break it down to smaller components that are more easily understood. HACCP allows growers or winemakers to determine which steps in the process are critical. Naturally, such plans are not only different for different people, but differ with different vineyards, wine types and styles. One would not expect the same list of critical control points for a mid-level and a premium product.

HACCP plans can be written in general terms to cover overall quality and stylistic goals, or can be created to focus on specific, particular grape growing or winemaking issues. The following is a review directed to the optimum management of sulfur-like off odors (SLO). SLO are derived from several sources and are members of the following chemical compounds.

- H2S

- Thiols or mercaptans: R-S-H

- Disulfides: R-S-S-R

- Thioesters: R-S-CO-R

- Fatty acids, 3-methyl-indole and 2-amino-acetophenone

In addition to the general incidence of SLO in wines, several important sulfur-containing compounds are gaining attention. Dimethyl sulfide (DMS) is believed to be synthesized by yeast from cystine, cysteine or glutathione. With aroma descriptors of truffle and quince, it is thought by some to have little or no direct negative aroma impact. However, DMS can modify the overall aroma and taste profile. Diethyl sulfide (DES) is a high-boiler-type SLO that has a garlic, rubber-type odor. DES can increase post-fermentation, is stable during aging and does not react with copper. As such, compounds like DES pose a significant potential problem, justifying a pro-active approach such as a HACCP plan.

A HACCP plan for the evaluation of SLO is designed to understand grape growing and winemaking steps that may impact the production of these compounds and how they may be managed. SLO have been around for the 8000 years of wine production. Naturally, a HACCP plan may not resolve all SLO issues, but may provide a much greater understanding of cause and effect, aiding management.

Figure 6.

In developing a list of CCPs for SLO management, growers and winemakers use their knowledge and understanding to create a HACCP outline (for a review of SLO issues, see Zoecklein, 2008).

CCP: Vineyard Management Practices. While a separate detailed viticultural HACCP plan can be developed, this discussion will highlight only a few vineyard concerns. The nitrogen required by yeast to conduct a healthy fermentation includes two forms, ammonia N, and a group of seven amino acids referred to as alpha-amino acids, or free amino nitrogen (FAN). Together, these two sources contribute the nitrogen utilized by yeast, referred to as yeast-assimilable (YAN), or fermentable nitrogen.

A number of viticultural and environmental factors can impact YAN and therefore, could be important CCPs in a HACCP. These include:

- Cultivar

- Rot incidence

- Block

- Vineyard mulch

- Crop load

- Moisture stress

- Maturity

From véraison onward, the following changes occur in the fruit:

- NH4+ increases, then declines

- FAN amino acids increase, then decline, with the rate of decline different among FAN components

- With extended maturity, YAN declines

There is a correlation between low concentrations of YAN and SLO formation. There also may be some complex relationships among YAN components that impact SLO, including high threonine, relative to other amino acids, and the relative methionine-to-ammonia concentration. Some SLO formation, including DES (diethyl sulfide), may suggest a careful review of fruit composition.

Some generalizations regarding cultivars and YAN are listed below. It should be noted, however, that site, season and vineyard management practices can have a very large influence.

- Merlot: usually low in YAN

- Syrah: usually somewhat low in YAN; this is coupled with high potential alcohol

- Pinot noir: often sufficient in YAN

- Sauvignon blanc: often sufficient in YAN

It is known that certain vineyard blocks consistently produce higher levels of SLO. Therefore a block may be a CCP. Block differences may be due, in part, to relative changes in quantity and/or relative proportions of YAN components. Such blocks or sub-blocks should be segregated and treated differently. Vineyard factors such as yield, maturity and incidence of fruit rot each can impact YAN and, therefore, may be CCP in a HACCP plan. For example, it is understood that rot can negatively impact YAN either directly and/or by lowering the concentration of micronutrients such as thiamine.

Figure 7.

Processing Variations. Processing variations may be a CCP for management of sulfur-like off odors. There is a relationship between juice extraction from the berry and YAN. This relationship stems from the fact that arginine, the FAN amino acid in the greatest concentration, is located mainly in the skins. Therefore, winemaking protocols, such as the following contrasts, may result in different YAN concentrations:

- Whole cluster pressing vs. crush and drain of whites

- Bleeding vs. non-dejuiced reds

- Short- vs. long-vatted reds

For those evaluating the N status of vineyard samples just prior to harvest, which I recommend, the relationship between sample-processing methodology and cellar processing must be noted.

High levels of sulfur dioxide (greater that 8 g/hL) could be a CCP (Figure 7). Such levels may increase the production of SLO by allowing sulfur dioxide to enter the yeast cell directly, bypassing the sulfate reduction system.

CCP: Non-Soluble Solids Level. Another possible CCP, listed in Figures 6 and 7, is the non-soluble solids (NSS) level, both pre- and post-fermentation. Turbidity of white juice should be adjusted with some precision, to attain stylistic goals and the aromatic finesse of the wine. Juice clarity can be measured in nephol turbidity units (NTU). The desirable NTU range is between 100 and 250. Low non-soluble solids concentrations going into the fermentor can result in a low concentration of YAN and other nutrients, and can increase the likelihood of SLO. High NSS concentration increases the risk of SLO production, including compounds difficult to remove. High non-soluble solids in the form of post-fermentation primary lees can deplete the oxygen content, lower the redox potential and increase the likelihood of SLO.

CCP: Cold Soak. Cold soaking is a common red wine production activity utilized in production of Pinot noir and other cultivars (See above section and Enology Notes and On-Line Publications at www.vtwines.info). Cold soak can cause quantitative and qualitative changes in YAN, as a result of extraction, absorption and possibly biotic factors. For example, it is known that yeast such as Kloeckera spp. can grow if the cold soak temperature is not below 10°C, resulting in a depletion of amino acids and micronutrients, including thiamine. It is possible that such activities could result in conditions that impact the production of SLO.

CCP: Oxygen Management. Because of the impact of oxygen on fermentation performance, oxygen may be an important HACCP CCP. Yeast produce membrane lipids only when grown aerobically. In the initial growth phase, proper oxygen management leads to proper production and storage of sterols in the yeast cell, which can be shared with subsequent daughter cells. It is possible to increase yeast ethanol tolerance by promoting synthesis of sterols, by adding oxygen (air) in the starter and during fermentation. Yeast lees deplete the oxygen content and can impact the redox potential and formation of SLO. Additionally, some yeast-derived commercial products aid in sterol synthesis. Oxygen management involves an understanding of the following:

- Optimum 8-10 mg/L oxygen during the initial growth phase

- Oxidative stress may be a primary cause of early yeast mortality

- Lees are potent oxygen consumers, even after yeast cell death

- Lack of oxygen can contribute to SLO

- Oxygen additions may allow yeast to produce more glutathione, an important white wine antioxidant

CCP: Yeast. Wine yeast play a central role in the production of volatile sulfur compounds, both the good and the bad. Yeasts are responsible for the transformation of non-volatile grape-derived precursorsto odor-active volatiles, which can positively contribute to thiol-based varietal character of a number of cultivars including Sauvignon blanc, Chenin blanc, Riesling, Petite Manseng, etc. Wine yeasts vary tremendously with regard to this conversion.

SLO production is controlled more by yeast genetics than winemaking, however fermentation environment does play a role. For example, the level of H2S can vary by as much as 2000-fold for a given strain, simply by changing the environment.

Some strains are less efficient users of nitrogen and have higher nitrogen requirements. Commercial strains can vary by more that 50% with regard to their N requirement. Additionally, uninoculated, feral fermentations, with a large population of non-Saccharomyces cells (therefore not alcohol tolerant) can cause problems. Non-Saccharomyces become inhibited by the increasing alcohol concentration, lose viability and undergo autolysis during the early- to mid-stages of the alcoholic fermentation.

CCP: Carbon Dioxide. Carbon dioxide is toxic to yeast and can impact cell performance. The release of carbon dioxide helps to minimize toxicity and decreases the lag phase of yeast growth. This is the time in which juice is most sensitive to both enzymatic and chemical oxidation.

Mixing during fermentation keeps the yeast in suspension, and helps to drive carbon dioxide out of solution, resulting in a lowering of carbon dioxide saturation. Mixing during fermentation may be important, regardless of the size and shape of the vessel. Some addition products contain inert compounds like micro-crystalline cellulose, the purpose of which is to help release carbon dioxide from solution, presumptively lowering the toxic impact.

Several other possible CCPs that may impact the production of sulfur-like off odors are outlined in the above figure. (For additional information see On-Line Publications at www.vtwines.info).

Step 3. Establish Limits for Each CCP.

A critical step in a HACCP plan is to establish acceptable ranges or limits for each CCP. This may involve chemical, physical, microbiological and/or sensory analysis. YAN has received considerable attention because there is a positive correlation, although not always strong, between low YAN and SLO production.

The nitrogen required by yeasts to conduct a healthy fermentation includes two forms, ammonia N, and a group of amino acids referred to as alpha-amino acids, or free amino nitrogen (FAN). Together, both sources contribute the nitrogen utilized by yeast, referred to as yeast-assimilable (YAN), or fermentable nitrogen.

The minimum yeast assimilable nitrogen required is approximately 140 mg/L for a 21°Brix juice, and perhaps 250 mg/L for a 23°Brix juice. However, it should be noted that these concentrations are broad-based generalizations for several reasons:

- The nitrogen level requirement to optimize fermentation is highly yeast-strain specific, governed largely by the genetics of the yeast.

- It may be that the qualitative makeup of FAN amino acids, not simply the total yeast assimilable N, is the most important factor. The significance of the qualitative nature of YAN helps to explain so-called reductive grapes, varieties that have a greater tendency to produce SLO. It also helps to explain seasonal and block differences in SLO production.

- A low concentration of assimilable nitrogen is often coupled with deficiencies in important micronutrients required for optimum yeast performance.

Step 4. Monitoring.

CCP monitoring involves chemical, physical, microbiological, and/or sensory analyses. With regard to YAN, two common procedures for measurement of fermentable N are the Formol titration and NOPA test. We modified the Formol titration procedure and compared the results with the NOPA method (Am. J. Enol. Vitic. 53:325-329). Some features of these two procedures are summarized below:

![Formal vs [OPA + NH3]](../images/EN139fig8.jpg)

Formol Titration.

- Simple titration procedure

- No instrumentation required

- Precise, but not extremely accurate

- Measures both FAN and NH3 N

NOPA Procedure.

- Measures FAN, but not NH3 N

- Must measure NH3 N separately

- Requires spectrophotometer

- Available in enzyme kit format

The Formol titration has the advantage of measuring both ammonia and FAN amino acids. However, the method titrates proline (which yeast cannot use) and does not react with all the nitrogen in arginine that the yeast may be able to use. Our research suggested that this generally balances out, although the proline/arginine ratio can vary significantly. Arginine accumulation begins well before véraison and continues to maturity, then plateaus. Proline, on the other hand, increases late in the season (four weeks post-véraison). High proline is associated with increased maturity and with vine stress.

Figure 8 shows the relationship between the two tests. As can be seen, the methods are comparable, demonstrating reasonable linearity. Formaldehyde is a carcinogen and must be used with caution. As such, we have developed a low-volume Formol procedure which is available at www.vtwines.info; under Industry Pubs, click On-line Publications, then Reduced Volume Formol Titration, adjacent to Fermentable Nitrogen.

In the wine industry, monitoring frequently involves sensory evaluations. One of the common difficulties is that such evaluations are frequently preformed under less-than-optimum conditions that can impact the sensory response. Sensory analysis must involve an understanding of the following:

- Standardized and controlled environment

- Representative sample

- Sample temperature

- Glass type, volume

- Elimination of bias

- Importance of sample contrasts

- Evaluators, who they are and their skills

- Number of evaluators required to gain a true picture

George Barkeley, the eighteenth century empiricist, suggested that our only knowledge of the world comes through our senses: “Esse est percipti,” to be is to be perceived. Perhaps the negative corollary is that if we do not perceive something in the glass, it is not there. Unfortunately, many winemakers sensorially evaluate under less-than-ideal conditions that may impact their perceptions (for information on sensory evaluation, see Zoecklein et al., 1999).

Step 5. Establish a Plan for Corrective Action.

With regard to low YAN, this would involve proper concentration and timing of supplement additions. Improper concentration and timing of N supplements can result in the following:

- Increased production of SLO

- Increased unwanted flora (if added too early or too late)

- Rapid fermentation

- Loss of volatiles, particularly if the source is DAP

- Decreased complexity

Too much nitrogen can stimulate the growth of unwanted organisms, increase the biomass, and cause too rapid a fermentation. Rapid fermentation can increase aroma compound loss due to increased volatility, resulting in the loss of complexity. Additionally, ammonia (in the form of DAP) can prevent the appearance of aromatic degradation products from amino acids.

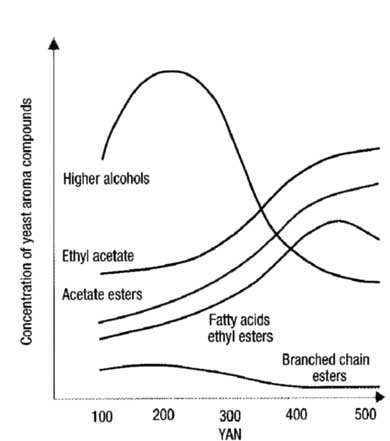

Amino acids are an important source of yeast-derived esters, which can add to complexity and wine quality. Thus, the supply of nitrogen must be available to allow a continuous re-synthesis of proteins. If that does not occur, the yeast lose the ability to conduct the fermentation. The various volatile groups found in wine and impacted by YAN are listed below. While this shows the trends observed, it should be noted that Figure 9 does not represent quantitative relationships among different chemical classes.

Figure 9.

Source: Ugliano et al., 2007

Nitrogen addition may be effective in avoiding problem fermentations until about two-thirds of the sugar is utilized. Cells which have passed the point of transcriptional responsiveness will not respond to added nutrients. It should be noted that there are significant differences between native (fruit-derived YAN) and addition products. Addition of nutrient products may not provide the same results as having an adequate native N concentration. As such, vineyard management which produces adequate fruit YAN may be very important.

Fermentation complements/addition products often contain some of the following:

- inorganic nitrogen (DAP)

- organic nitrogen (alpha-amino acids)

- unsaturated fatty acids

- sterols, thiamine, folic acid, niacin, biotin and calcium pantothenate

- magnesium sulfate

- inactive yeast cell walls

- peptides

- micro-crystalline cellulose

- other yeast autolysis products

The possible benefits of complex yeast nutrient (CYN) addition products include better resistance to oxidation as a result of increases in glutathione, higher levels of free sulfur dioxide, better color, and increased protection of aromatic quality. The reader should consult manufacturers’ product literature for discussions regarding nutrient additions and timing. There are currently time-release nutrient products available.

Post-fermentation, it is important to conduct a careful sensory review of SLO. If SLO are present, it is essential to conduct a sulfite aroma screen (see Zoecklein et al., 1999). One possible post-fermentation corrective method involves the addition of inactivated yeast (30 g/hL). Yeast and materials in some proprietary products can bind with some SLO. Inactive yeast is thoroughly mixed in a laboratory trial and evaluated after one week against an untreated control wine. If this treatment is not effective, conduct a sensory evaluation with copper sulfate, followed by yeast fining or the addition of inactivated yeast product. Copper is a strong oxidizing agent which can deplete glutathione, and impact wine longevity (see Zoecklein, 2008) so it is essential to avoid the addition of copper when possible.

Step 6. Establish an Adequate Record System.

In the ever-more competitive global marketplace, it is essential that overall wine quality move forward, not laterally from one vintage to the next. A HACCP plan aids in that effort. Such a plan must be supplemented with adequate recordkeeping. Choosing the optimum software for your vineyard and winery operations requires an understanding of your needs, cost of software, training required, update availability, etc.

Step 7. Develop A Verification Plan for Analyses Utilized.

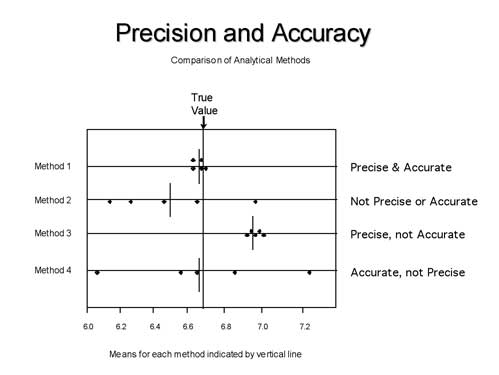

There are two important questions to ask: Do you know the precision and accuracy of the analysis that you are using? Are your sensory evaluations done with the proper level of controls? An example of the differences between precision and accuracy is illustrated in the Figure 10, below. Four methods are shown. The means of the five data points is indicated by a vertical line and can be compared to the true value.

Figure 10.

Conclusion.

HACCP represents a systemic approach to grape and wine quality control that can be tailored to specific production issues and considerations. It can assist in understanding the impact of the marinade of individual processing decisions that individually may seem insignificant, but collectively impact your product palatability and style.

It is what you learn after you think you know it all that really counts.

![]()

Subscription to Enology Notes. All past Enology Notes newsjournals are posted on the Enology-Grape Chemistry Group's web site at: http://www.vtwines.info/.

To be added to (or removed from) the Enology Notes listserve send an email message to with the word "ADD" or "REMOVE" in the subject line.

Dr. Bruce

Zoecklein

Professor and Enology Specialist Head Enology-Grape Chemistry Group

Department of Food Science and Technology, Virginia Tech

Blacksburg VA 24061

Enology-Grape Chemistry Group Web address: http://www.vtwines.info/

Phone: (540) 231-5325

Fax: (540) 231-9293

Cell phone: 540-998-9025

Email: