Enology Notes #164

An Alphabetical Subject Index for all past Enology Notes:

All past years' Enology Notes are still available in the Yearly Index. Use this link to jump to the most recent year's index: 2013 Enology Notes Listing.

Enology Notes #164 January 25, 2013 - Link to PDF

To: Grape and Wine Producers

From: Bruce Zoecklein, Head, Professor Emeritus, Enology-Grape Chemistry Group, Virginia Tech

Subjects:

- Bordeaux and Spain Technical Study Tour, A Review

- Vinitech

- Winery Planning and Design, Edition 16, Available

- My Retirement and Replacements

- Upcoming Meeting Reminders.

1.Bordeaux and Spain Technical Study Tour, A Review.

A French colleague, Pascal Durand, and I led our 7th Technical Study Tour to France and Spain in early December. The following is a brief overview.

Spain. In Spain, we visited producers in Rioja and the Getaria region. The landscape of Rioja is austere and beautiful, and contains three general winegrowing areas: Rioja Alavesa, Rioja Baja, and Rioja Alta. The Rioja was propelled by a wave of investment in the late 19th century. These traditionally-styled wines are aged, and usually supple with flavors of dried fruit, spice, and tobacco. By the late 20th century, a modern revolution hit Rioja, not unlike that of Napa and elsewhere. Styles changed, with wines becoming “richer” and more heavily structured. Today, many are using a combination of both traditional and New-World winegrowing, resulting in wines which are fresh, with some acidity and longevity.

We stayed in the village of Elciego, the heart of Rioja Alavesa. It is in this region that the modern winemaking history of Rioja began. In 1858, Marqués de Riscal and the Guillermo Hurtado de Amézaga families, which had been expatriated to Bordeaux, returned to their own vineyards in Spain. Working with consultants from Bordeaux, they began a technical revolution.

During this period, many of the vineyards were planted to Bordeaux varieties. What followed, however, were decades of war, including the Spanish Civil War with economic and political distress slowing development. In the 1990s, things began to change, including the production of well-structured red wines made from Tempranillo, Garnacha, Mazuelo, and Graciano, with only limited Bordelais varieties included. Additional changes followed, including the now common practice of bodegas owning and managing their own vineyards, rather than buying grapes.

The label terms crianza, reserva, and gran reserva, a system for designating aging, are no longer considered essential for many industry members. They explain to the consumer how long a wine has been in barrel, but do not say anything about the quality.

Eduardo Eguren, a 5th generation winegrower, is an example of the new face of Rioja. His grandfather, Guillermo Eguren, is the patriarch of one of Rioja’s most successful wine families. Eduardo studied enology at Artadi, and worked in Santa Barbara and Sonoma, before returning to his family’s many wineries. We toured many of his vineyards and his family’s original home, and had a series of extensive tastings of various terroirs. Their production is a blend of the old and new. For example, we evaluated a white wine from the variety Viura, produced by inoculation of Pichia sp. (an indigenous yeast), followed by Saccharomyces sp.

Despite the general perception of Spain’s economy, there are a number of very well financed, state-of-the-art wineries that are architectural wonders in the Rioja region. In the early 19th century, Bordeaux wineries were the mark of tradition and architectural provenance. In the last half of the 20th century, it seemed that New World regions, and particularly Napa Valley, were the home of innovative architecture. In the early part of the 21st century, that innovation is certainly evident in Spain.

Bodegas Baigorri

Bodegas Baigorri is an ultra-modern, seven-level gravity-flow facility, located in the medieval town of Samaniego. The top level is a large transparent cube which provides spectacular and uninterrupted panoramic views of the vineyards, the rolling hills, and the town beyond. Like a beacon, this top pavilion is the main face of the winery and the first entry point, with the production activities set below ground.

Bodegas Marqués de Riscal is a hotel, restaurant, and winery in Elciego. This unusual and award-winning architectural design of Frank Gehry makes a stunning contrast to the surrounding 19th century cellars

Dinastía Vivanco, near the village of Briones, is home to both a very impressive winery and one of the world’s most elaborate wine culture museums. Established by the Dinastía Vivanco Foundation, the goals are to investigate and educate about the culture and history of wine. Visiting this museum is a must for anyone interested in wine culture and the impact of wine on human civilization.

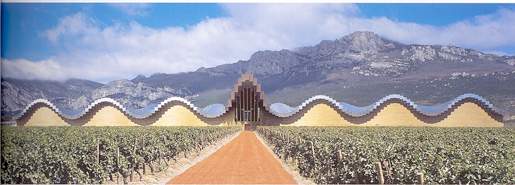

Ysios, named for the Egyptian goddess of wine, is located at the edge of Spain’s premium winegrowing region. The winery provides an unforgettable image – a wave of wood and aluminum that is designed to mimic the Cantabrian mountain range in its background. The curvilinear roofline is designed to minimize the impact of the 640-foot-long building. This is the winery that was on the cover of our 15th edition of the Winery Planning and Design CD.

From Rioja we traveled north to the seaside village of Getaria. known for a white wine called Txakolí. This unique white wine is made from a blend of Hondarribi Zuri (95%) and Hondarribi Beltza (5%). The wine is fruity, dry, low alcohol, and slightly effervescent. The vineyards that produce Txakolí are grown on arbors that line the green slopes of this very esthetic village. This is a must-see.

Bordeaux. In France, we enjoyed the unique privilege of tastings and technical exchanges with the winegrowers of some of the most prestigious houses in the world, including Château Margaux, Château d’Yquem, Château Palmer, Château Smith Haut Lafitte, Château Faugères, Château Cheval Blanc, Château Lynch-Bages, Château Cos d’Estournel, Château Climens, Château La Louviere, and the ISVV (L’Institut des Sciences de la Vigne et du Vin). The Bordeaux regions explored included Pessac Léognan, Margaux, Saint-Estèphe, Pauillac, Saint-Émilion, Graves, Barsac, and Entre Deux Mers.

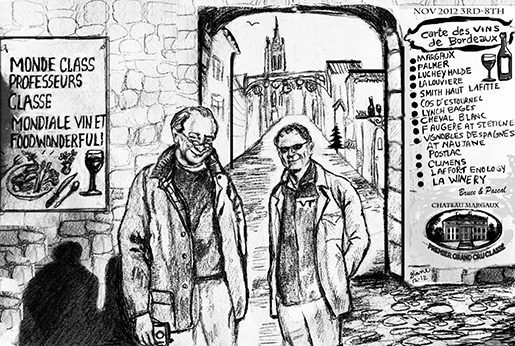

Professors Durand and Zoecklein, a drawing by Diane Canney of Sunset Hills Vineyards, VA

Much of our time was spent discussing viticultural issues with our Bordeaux winegrowing colleagues, including organic and biodynamic (BD) farming. Some, like Frédéric Nivelle of Ch. Climens at Barsac believe that BD increases the acidity and freshness of wines. Biodyamics allows for vine heterogeneity, that is, it prompts vines to be morphologically (physically) different, which promotes sensory complexity.

Also discussed were the differences in the gravel-, clay-, and sand-soil profiles of various Bordeaux sub-regions. These differences impact water-holding capacity, mineral uptake, soil temperature, etc., which in turn impact vine water, vegetative growth, ripening rate, and fruit composition.

The French do not irrigate (except for vine establishment). One interesting comment offered by Kees van Leeuwen of Château Cheval Blanc is the opinion that many in the California wine industry irrigates too extensively. He points out that so-called “dry” soils hold about 12 inches of water, and that grape vines are quite resistant to drought if adjusted relatively slowly.

Climate change is an important topic that the French wine industry has been concerned about for some time. Changes in climate may impact both cultivar and clonal selection choices. For example, it would be desirable to have both cultivars and clones that mature in mid-October, rather than in August. The premise is that the last stage of ripening should occur in relatively cool weather.

Like most, the French wine industry is concerned about the use of agricultural chemicals, with most members professing to be either organic or biodynamic. However, it was suggested that some of the most prestigious vineyards may use more chemicals, simply due to the value of their crop and fear of lost revenue.

Study Tour participants at Château d’Yquem

At Château Palmer, we had a discussion on the effects of co-fermentation (the addition of both cultured yeast and bacteria at or near the beginning of fermentation). While popular both in New World winemaking and in France, the practice was questioned by Sabrina Pernet, the technical manager of the château, who wondered if the same anthocyanin-tannin polymerization occurs under such conditions, vs. post-fermentation MLF (See Enology Notes #160 for a discussion on polymerization of phenols).

Kees Van Leeuwen, of Château Cheval Blanc, asked if one should expect the same sensory results with co-fermentation, where the MLF bacteria are metabolizing at a much higher temperature, than would generally occur with traditional post-fermentation MLF in the early spring. Cheval Blanc does not co-inoculate.

As is common in New World wine regions, almost every French vigneron is concerned with Brettanomyces. Several expressed the belief that managing vineyards biodynamically helps to control Brett in the cellars. There were several reports of new cellar establishment, using only new wood, which later developed Brettanomyces in the cellar. This provides empirical justification for the concept that Brett does come in from the vineyard, despite the belief of some.

As is the case in most wine regions, gentle cap management is the norm. Indeed, several winegrowers reported as much as a 40% reduction in mechanical cap mixing in the last several years.

Château Faugères is a modern five-level gravity-flow facility that, like several we visited, uses an interesting red wine barrel fermentation technique. Destemmed berries are put into a sorter that selects berries, based upon size. Berries are then conveyed into new French 220-L barrels by gravity. Barrels are on AXO-type barrel-stacking systems, with each barrel fitted with a stainless steel deporting plate on the head, and a secured gas release valve bung. These non-yeast-inoculated barrels then are rotated four times per day during fermentation. At the end of fermentation, wine from one barrel is added to another to allow full barrels to undergo extended maceration. This whole-berry barrel fermented wine is used as a blending adjunct.

We also visited La Winery. The term winery is not used in France. As such, a group of innovative businessmen registered the name and are using it for some creative retailing. At La Winery, new customers can participate in a sensory evaluation of six different wines. Following the evaluation of each, participants answer several questions electronically. At the end of the tasting, they are given a “cellar book” which highlights their wine preferences. Preferences are divided into eight categories, each color coded. In the retail area, wines are grouped according to these color codes to allow for easy selection of preferred wine types and styles. This system is not unlike the Vino typing categories of wine consumers, which was outlined and discussed by Tim Hanni during several meetings in Virginia. More information on La Winery is available at www.winery.fr.

We also visited Vinitech, reportedly the largest grape and wine industry equipment show in the world, with over 40,000 attendees and 800 exhibitors. The following are a few comments about some of the equipment that I thought was either unique or that had won innovation awards. Additional information about the items below is available by contacting my office.

Aerobic Digester. An aerobic biological process for treating winery effluent by composting crushed vine shoots, either alone or mixed with other organics, such as pomace, etc. The process is automated, including all the steps involved in composting (storage, turning, mixing), requiring no manual effort. The resulting compost is reportedly of higher quality than that obtained from traditional manual systems.

Electronic Bung System for Monitoring the Cask/Barrel Maturing of Wines and Spirits. A network of wireless sensors incorporated into individual casks for monitoring. It allows simultaneous measurement of the level of headspace and in-barrel pressures. When the pressure changes, the system alerts the user. This allows for rapid intervention, as measurements can be taken with much greater frequency than is possible using manual measurements via bungs. The monitoring software also triggers alarms, if desired, to remotely measure temperatures.

Dynamic Press. A dynamic press equipped with a hopper and a centrifugal wheel which collects fruit, and a fixed wall against which the centrifugal wheel projects the grapes. The principle is to allow the complete pressing of every berry passing through the system by applying kinetic energy and a convergent movement towards a fixed pressing wall.

Automatic Wine Filtration System. An automatic wine filtration system employing 30-inch filter cartridges (the user can select pore diameters). It is equipped with software to manage and optimize filtration parameters (pressure, flow, volumes filtered). At the start of filtration, a filterability test is run for the first 10-15 minutes at constant pressure. Depending on the results, the software then optimizes filtration parameters, including pressure management, flows, washing, and regeneration.

Inline Gas System. An inline CO2, nitrogen or argon injection tool that can be used to carbonate, decarbonate, and deoxygenate wines in the winery or at packaging/bottling. The injected gas is adjusted according to the flow and temperature of the wine, which is controlled inline. Injection is via a stainless steel sintered element, controlled by a micro-oxygenation dosing chamber.

Automated Chill/Freeze Tunnel. A cooling tunnel for grapes, either whole or de-stemmed, using N2 or CO2 on a stainless steel wire mesh belt. Using atomized liquid gas, this equipment provides adjustable and continuous temperature control for either hand-picked or mechanically-harvested fruit. The tunnel consumes an average of 120 L of liquid N2 per ton. On this basis, to reduce the temperature by 10-15°C, the operating cost would be around $120-220 per ton of grapes.

3. Winery Planning and Design, Edition 16, Available.

This publication, in CD format, is the result of a number of short courses and seminars, covering various aspects of winery planning, held in several wine regions around the country. While not regionally specific, the information provided is from a number of authoritative sources, covering such diverse topics as sustainable design, winery equipment, and winery economics. Winery Planning and Design, Edition 16, is available through the industry trade journal Practical Winery and Vineyard (phone 415-479-5819, email: ). The entire index and additional information is available at www.vtwines.info.

4. My Retirement and Replacements.

I retired from Virginia Tech in 2010, but agreed to remain part-time for three years while the University secured funds for my replacement. Virginia Tech made the decision to replace my position with two faculty positions. One will be 100% enology extension, and the other enology teaching and research.

Molly Kelly, will be Virginia Tech’s new Enology Extension Specialist. Ms. Kelly joined the faculty of the Department of Food Science and Technology on December 25, 2012.

The second position for research and teaching is currently being advertised. Information on this position is available at http://listings.jobs.vt.edu/postings/36907.

Enology Notes will continue and will be authored by myself, Molly, and others.

5. Upcoming Meeting Reminders.

Virginia Vineyards Association meeting January 31- February 2. Information is available at www. virginiavineyardsassociation.com

Mid West Grape and Wine Conference February 7-9, St. Louis, MO. Information available at www.midwestgrape.com

The Virginia Wine Exp February 19-24, Richmond, VA. Information available at www.virginiawineexpo.com

The Eastern Wine Exposition March 6-7, Lancaster, PA. Information available at www.easternwineryexposition.com

Wineries Unlimited 2013 March 12-14 in Richmond, VA. Information available at www.wineriesunlimited.com