Enology Notes #153

All past years' Enology Notes are still available. Use this link to jump to the most recent year's index: 2010 Enology Notes Listing.

Enology Notes #153, March 11, 2010 - Link to PDF

To: Grape and Wine Producers

From: Bruce Zoecklein, Head, Enology-Grape Chemistry Group, Virginia Tech

Subjects:

1. Bordeaux-Variety Red Wines: Where are we? Where do we need to be?

1. Bordeaux-Variety Red Wines: Where are we? Where do we need to be? Most premium winecrafters have established a winemaking philosophy and practices which reflect how they believe they can best reveal the expression of their vineyard sites each season. The goal is usually to create wines that delight, impress and/or intrigue (Smith 2010).

Where are we with regard to our understanding of crafting fine Bordeaux-variety red wines? What do we need to do to improve?

A look at some of the important viticultural and enological considerations reminds us of both the kaleidoscope of decisions required, and how rapidly our philosophy and practices have changed in the last 10 years, 5 years, or even the last 3 years.

Vineyard Issues

- Soil composition

- Drainage/water management

- Clone

- Rootstock

- Canopy architecture

- Crop balance, components of yield

- Rate of maturity

- Maturity date

- Degree of berry shrivel

- Extent of berry and cluster variation

- Potential alcohol

Winemaking Issues

- Fruit sorting

- Degree of berry breakage

- Destemming

- Post-destemming sorting

- Pumping methods

- Cold soak temperature and duration

- Yeast strain/co-fermentations/uninoculated fermentations

- Vessel size

- Vessel type

- Heat management

- Oxygen management

- Sulfur dioxide management

- Inoculated vs. non-inoculated MLF

- MLF strains

- Timing and duration of MLF

- Effect of pH adjustment on volatiles

- Cap management type, duration

- Timing of dejuicing

- Press fractions

- Lees management

For Bordeaux wines, the above variables can be distilled down to impacts on the following:

- Vine balance

- Fruit composition

- Effect on co-extraction

- Structural/textural stabilization

Each of these has an influence on component parts, including color, aroma/flavor, mouthfeel and overall balance. The epistemology of our knowledge brings us to certain conclusions, as outlined by Smith (2010):

- Enology has fundamental limits.

- Wine is a colloidal matrix, not simply a solution

- Qualitative features may be as important as quantitative.

Traditional enology has been useful in recommending how to make wines with few defects. However, it has done less to advance the understanding of how to promote excellence. As is frequently the case, modern winemaking has solved the easy problems and left behind the more challenging ones (Smith 2010).

We no longer look at color, aroma, and flavor as the sum of their pieces. That is, we view wine not as an analytical sum of its parts, but as a complex colloidal matrix, the components of which act synergistically and antagonistically. The colloidal nature of wine suggests that particles of different sizes and shapes interact to integrate aroma/flavor and mouthfeel. The knowledge that wine acts like a colloidal mixture has promoted our understanding of processing impacts, including juice extraction, fining and filtration.

Within limits, the properties of wines depend less on their composition and more on their structure. That is to say, there are both quantitative and qualitative features. This is notably evident when it comes to the impact of phenols on mouthfeel.

a. Color. What have we learned about wine color of Bordeaux-variety red wines? Anthocyanins are phenolic compounds which, when extracted from grape skins, help provide red wine color. Water deficiency increases anthocyanins and lowers malic acid, while the effect on sugar concentration may be variable.

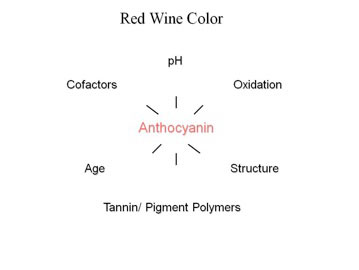

We know that visible color is a function of an entire constellation of factors listed below (Figure 1), not simply the amount of anthocyanins extracted from the fruit.

Figure 1. Factors influencing red wine color.

Figure 1. Factors influencing red wine color.

(Adapted, in part, from Kennedy 2008.)

Humans are very visually oriented. As such, wine color adds a bias to our evaluations. A classic example of this bias is to change the hue of a wine by adding varying concentrations of food coloring. If the red hue is diminished, the resultant wine will show a different sensory rating red or fullness, body and complexity. People believe that deep, rich-colored wines will have high volume/body and softer tannins. Conversely, it is assumed that a wine with less red color will have so-called ‘green’ or ‘harsh’ tannins.

Anthocyanins are critical to good red wine mouthfeel. These compounds act as the “book ends” on the polymerization process, binding with tannins and limiting the degree of polymerization. As such, the ratio of tannin to anthocyanins is important (4 to 1). Anthocyanin polymers impact color, color stability, and wine mouthfeel.

Colorless cofactors (Figure 1) create more color than would simply result from the anthocyanin concentration. This co-pigmentation phenomenon is perhaps more important for low-colored varieties than Bordeaux wines (see Enology Notes index).

What is on the horizon? While anthocyanins relate to subsequent red wine color, measurement in the fruit may best be used as a means of determining vineyard lot uniformity (see Enology Notes #151). Currently, we have sensors that can be used in the vineyard for measuring berry color. We have sorters that can take pictures of bins and segregate based on color. In the near future, we will have sorting tables that will separate destemmed berries based on color.

b. Tannins. What have we learned about tannins? There are several important positive correlations.

- Red wine quality (however defined) is correlated to total phenols.

- Red wine quality is more strongly correlated to skin tannins and, specifically, a certain group of skin tannins.

The global issue is balance, and how much tannin can be supported by the fruit perception in the wine. Tannin production proceeds prior to véraison, and maturation effects qualitative changes. Sugar accumulation rate is important to tannin development. Tannins are also influenced by a number of additional factors, including:

- Low nitrogen

- Low soil moisture

- Low soil fertility

- Moderate crop size

- High sun exposure

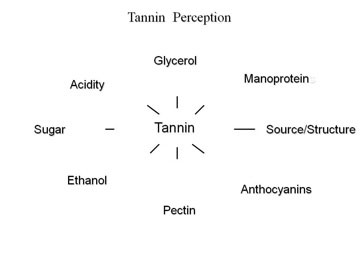

Tannin perception is a function of a number of features, including those listed (Figure 2).

Figure 2. Factors influencing tannin perception. (Adapted, in part, from Kennedy 2009.)

As a function of processes such as délestage and controlled oxygenation, we have learned the art of building structure through controlled oxidative polymerization. The complete package has been our understanding of the advanced use of lees and completely re-thinking the role of barrels.

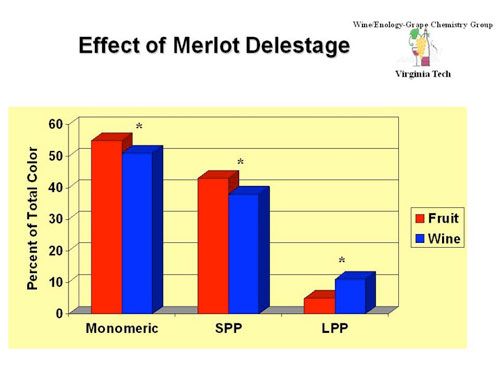

Figure 3. Polymeric pigments in Merlot.

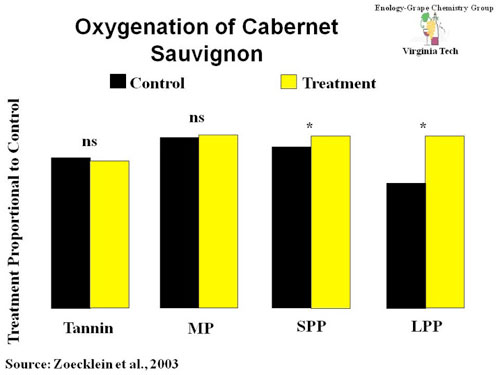

Figure 4. Tannins and polymeric pigments in Cabernet Sauvignon.

Figures 3 and 4, from research conducted in my lab, illustrate the impact of processing (délestage and oxygenation) on the association of monomeric anthocyanins (MP) with tannins to create small and large polymeric pigments (SPP and LPP). Color caps off the tannin polymerization, producing wines with finesse (see Enology Notes index for additional information).

What is on the horizon? To many, the Holy Grail is to have a tannin assay that is simple and that could be done at the winery. Such a measure could be of value in increasing our understanding of the relationships between grape growing, wine processing, and tannins (Kennedy 2010). A simple test that differentiates tannins, based on size and structure (including tannin-pigment polymers), would be ideal. It should be noted, however, that the perception of astringency is not simply a function of the qualitative and quantitative nature of tannin phenols, but each of the factors in Figure 2.

c. Aroma. What have we learned about red wine aroma? We no longer seek to simply pump up the positive attributes of the wine Aroma Wheel, and suppress the negative ones. Instead, we try to merge all the wine’s aroma/flavor into a coherent whole. High-vigor vines and high yields can result in poor fruit chemistry, including high methoxypyrazines. We need to control growth by limiting water (when possible) and nitrogen, both of which can impact grape aroma.

Aroma measurement has been difficult for several reasons, including the complexity and variety of compounds and their concentrations. For example, while color and tannins are in concentration levels of parts per thousand to parts per million, aroma/flavor volatiles are often present in parts per trillion. This has made it difficult for winemakers to evaluate them. Currently, we use sensory evaluation techniques such as BSA (berry sensory analysis). These are subjective and, therefore, not easily quantifiable.

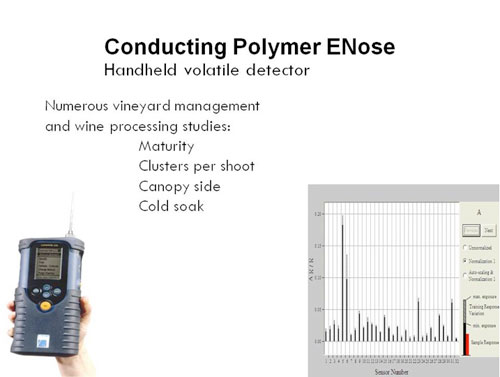

Figure 5. Electronic nose and sample

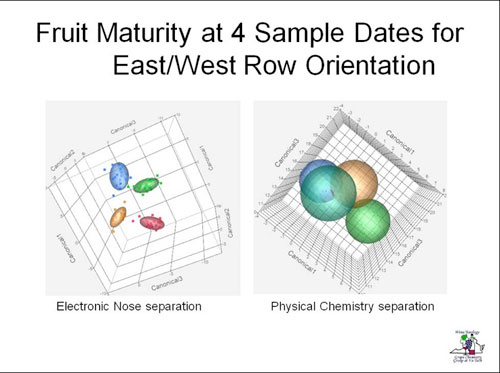

Figure 6. Canonical distributions of “smell print.” electronic nose and physico-chemical analyses.

We have used electronic nose (Enose) technology (Figures 5 and 6) as a tool to evaluate the impact of several grape growing and winemaking practices on aroma, including fruit maturity, clusters per shoot, grapevine canopy side, and cold soak. Figure 5 illustrates a hand held conducting polymer electronic nose and the ‘smell-print’ pattern it creates. Figure 6 (adapted from Devarajan et al 2010) demonstrates a comparison of 11 maturity indexes with the electronic nose evaluation of grape volatiles. These are canonical plots that represent the multivariate means of data as circles whose size indicates the 95% confidence limit of the mean. Non-interesting circles indicate signification differences. As can be seen, the electronic nose does a better job of discriminating and in vastly less time.

The use of such a tool allows us to monitor the impact of some viticultural and winemaking practices on volatile compounds (for additional information go to www.vtwine.info; see either on-line publications or Enology Notes).

What is on the horizon? We are working on a conducting polymer-based electronic nose system that has but a few (less than 30) conducting polymers specific to certain groups of wine cultivars.

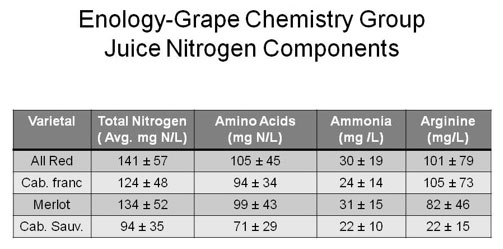

d. YAN. We now understand the fundamental link between yeast assimilable nitrogen concentration (YAN) and wine aroma. Aroma is qualitatively impacted by juice nitrogen, both by too much and too little. For three seasons, the Enology–Grape Chemistry Group’s Enology Service Laboratory has evaluated the N content of juice for the industry in real time, allowing for adjustments when needed (Figure 7). Such evaluations and focused adjustments have lowered the incidence of SLO (sulfur-like off odors) and increased the production of desirable aroma volatiles. (For additional information go to www.vtwines.info. See either Enology Notes or on-line publications.)

Figure 7. Juice nitrogen content.

What is on the horizon? It is postulated that YAN measurements could be a good barometer of the nitrogen status of the plant. Currently, our lab and others are evaluating those relationships.

2. Industry Challenges. As suggested by Grahm (2010) in order for the industry to move forward, not laterally, from one vintage to the next, we need to keep Ray Koch’s famous remark in mind: “You cannot manage if you cannot measure.” I would modify those comments, however, to suggest: You cannot understand if you cannot measure. How much management can be a philosophical debate. There is no debate that increasing our knowledge base has the potential to improve our wines. Our challenges in crafting fine wines include the resolution to these questions, adapted, in part, from Dokoozlian (2010):

- Vineyard management and fruit chemistry.

- What are the relationships between fruit chemistry and wine chemistry

- What are the relationships between wine chemistry and sensory properties?

- What are the relationships between sensory properties and consumer perception?

The key driver is to link chemistry with sensory perception. To some, this mechanistic approach may seem contra natura, against their philosophical nature, too technocratic and against artistic winemaking.

However, this goes to the core belief that luck is the residue of design. Fine winecrafters should espouse to the general mantra: keep things as simple as possible, but not simpler. The answer to these questions allows such a practice.

How do we, as an industry, improve?

We must understand our goal(s).

In the environment of New World wines, we have two distinctively different products, as suggested by Soter (2009) and Grahm (2010):

- Beverage/industrial/vins de efforts

- Agricultural/terroir/vins de terroir

Beverage wines are products that are consistently made by a standardized process, and are designed to please most people. Such wines are referred to by some as industrial wines, or vins de efforts (Grahm 2010). The proliferation of wine additives and adjuncts allow for a certain homogeneity of such wines.

Agricultural wines, also known as terroir wines, on the other hand, can be characterized as having some uniqueness, subtlety, and avoidance of mediocrity.

There are those who believe that high quality wine can only be achieved by water deficit, suggesting that there is no terroir effect without water deficit. However, to Soter (2009), the way of differentiating is to simply ask the question: Could this wine exist in nature? The heart of this question is: What processes are acceptable to you? In order to understand the full potential of a variety, we need to be able to evaluate the full intrinsic potential of the grape.

How do we, as an industry, improve?

We must also understand the difference between empirical or observational data, and science-based knowledge. We must understand the limits and merits of each.

As indicated, enology does not have all the scientific knowledge to promote excellence. On the other hand, secondhand empirical knowledge (also known as hearsay) is sometimes faulty, because what applies to one circumstance may not to another.

The question is one of relativism. What information is universal, and what information is specific to time, place, and circumstance?

As an industry, this distinction is sometimes blurred. An additional problem with relying too heavily simply upon empirical observations is that, if two outcomes are similar, we have a tendency to assume they must have a similar cause. This may or may not be correct.

This problem goes back to Francis Bacon and beyond, who reminded us, “Genius is like fleet of foot, method is the right path. Fleetness of foot on the wrong path never leads to knowledge.”

We need to know what we know, and know what we don’t know. That is a good definition of knowledge. And besides – it is what you learn after you know it all that really counts.

3. Winery Planning and Design, Edition 16, Available. This publication, in CD format, is the result of a number of short courses and seminars covering various aspects of winery planning in several wine regions around the country. While not regionally specific, the information provided is from a number of authoritative sources covering such diverse topics as sustainable design, winery equipment, and winery economics. Winery Planning and Design, Edition 16, is available through the industry trade journal Practical Winery and Vineyard (phone 415-479 5819), email: or . Additional information is available at www.vtwines.info.

![]()

Subscription to Enology Notes. All past Enology Notes newsjournals are posted on the Enology-Grape Chemistry Group's web site at: http://www.vtwines.info/.

To be added to (or removed from) the Enology Notes listserve send an email message to with the word "ADD" or "REMOVE" in the subject line.

Dr. Bruce

Zoecklein

Professor and Enology Specialist Head Enology-Grape Chemistry Group

Department of Food Science and Technology, Virginia Tech

Blacksburg VA 24061

Enology-Grape Chemistry Group Web address: http://www.vtwines.info/

Phone: (540) 231-5325

Fax: (540) 231-9293

Cell phone: 540-998-9025

Email: