Enology Notes

Enology Notes #127, March 21, 2007

To: Regional Wine Producers

From: Bruce Zoecklein, Head, Enology-Grape Chemistry Group, Virginia Tech

Subject: News from Ken Hurley, the Director of Virginia Tech’s Enology Service Lab: Incidence of Reductive Odor Defect; Vineyard Management and Wine Quality – Spray Impacts; Copper; Elemental Sulfur and Volatile Sulfur Compounds; Viticultural HACCP; Dragon Wines – The Chinese Wine Industry (continued); Congratulations to Emily Hodson Pelton.

1. News from Ken Hurley, the Director of Virginia Tech’s Enology Service Lab: Incidence of Reductive Odor Defect. The Enology Analytical Services Laboratory started receiving samples one year ago, on March 21st. When the lab was established, it was required to be self-sustaining through income from analyses performed within two years. After one year, we are close to obtaining that goal.

In previous issues of Enology Notes, I have suggested reasons for using any laboratory service. At this one-year juncture, the reasons for regional winemakers using a laboratory service become very clear. Our lab has received hundreds of samples from across the country and, indeed, around the world, and performed thousands of tests.

The wine defect that stands out most significantly is the presence of volatile sulfur compounds. At any given time, greater than 25% of the wine samples in the lab contain detectable levels of reductive odor defect.

Detailed information regarding volatile sulfur compounds can be found in previous editions of Enology Notes, # 26, 71, 79, 84, 93, 95, 101, 102, 105, 108, 113 (www.vtwines.info). Off-odor volatile sulfur compounds are formed for a variety of reasons, including lack of fermentable nitrogen. The type of nitrogen added to the juice/must, and the timing of the addition, can have significant impact.

Prior to bottling, all wines should be reviewed expressly for determining the presence of off-odor volatile sulfur compounds. A simple aroma screen for off-odor volatile sulfur compounds is provided in Zoecklein et al. (1999).

Treatment of mercaptans usually involves addition of cupric sulfate, but addition may strip favorable aroma components from the wine. The best treatment is prevention. As vineyard owners and winemakers develop HAACP plans (Enology Notes # 8, 22, 32, 75, 115) for the upcoming growing season, they should consider adding juice testing for fermentable nitrogen and a review of the many other factors to prevent off sulfur-based aromas. A slide show on Volatile Sulfur Compounds, given by Dr. Zoecklein in New Zealand, is on the Enology-Grape Chemistry Group website at www.vtwines.info. Click on-line publications.

2. Vineyard Management and Wine Quality – Spray Impacts. Grape growers must not lose sight of the fact that they are growing wine. As such, growers are active participants in viticultural winemaking, by far the most important part of the process. The following is a review of some issues regarding vineyard spray impacts I discussed at the winter meeting of the Virginia Vineyards Association.

Fruit rot potential is a part of grape growing in many parts of the world. Management usually involves the following:

- Sorting fruit in the vineyard and at the winery

- Spray programs

- Wine process adjustment when there is visible rot

Certainly in the mid-Atlantic region, all premium wine produces must utilize some sort of fruit sorting. Many use multiple sorting, including vineyard, pre-destemming at the winery, and often post-destemming. It is well established that even a relatively low incidence of fruit rot can impact yeast fermentation, bacterial fermentation, and potential wine quality. Those impacts include the following:

- Stuck or protracted fermentations, yeast and/or bacteria

- Change in yeast population dynamics-either on the fruit or during ferm.

- Off odor/flavor

- Oxidation, loss of aroma/flavor intensity

- Shortened longevity

- Haze and/or precipitates

- Ochratoxin

Our challenge is to balance the need for controlling rot incidence with the desire to limit vineyard spray applications. Some spray materials, if added late season, are known to negatively affect wine quality. Those impacts include:

- Stuck or protracted fermentations, yeast and/or bacteria

- Change in yeast population dynamics-either on the fruit or during ferm.

- Off odor/flavor

- Oxidation, loss of aroma/flavor intensity

- Shortened longevity

- Haze and/or precipitates

- Perception

The list of negative impacts of some spray residues is similar to the list of impacts from rot. An important exception is perception. The concern regarding agricultural chemicals is universal and increasing.

Winemakers’ initial concerns regarding spray residues and fruit rots are focused on the impact on yeast fermentation. While important, a review of both lists above suggests that yeast fermentation is but one of many potential concerns.

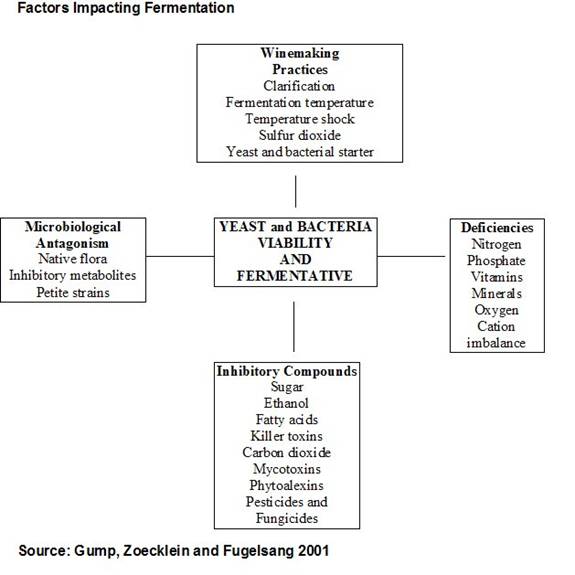

The figure below categorizes fermentation impacts. The group of fruit deficiencies, inhibitory compounds, microbiological antagonists, and winemaking practices that can each affect fermentation is provided. Each category can be affected by rots and certain spray residues.

In the case of spray materials, the impact can be in the utilization of important minerals, creating a deficiency, causing the yeast or bacteria to produce toxins and/or directly inhibiting cellular function.

Seldom is any single factor the cause of fermentation problems. More frequently, synergistic interaction of several limiting or inhibitory conditions listed above negatively impacts fermentation. For example, a low incidence of sour rot can deplete the thiamine concentration of the fruit. Thiamine (vitamin B12) is needed by yeast for protein synthesis.

A limited depletion of thiamine may have no impact on yeast fermentation or could be compounded or magnified by other deficiencies and/or antagonists such as spray residues. For example, Captan can negatively impact fermentation, particularly in the presence of other limiting or inhibition factors.

Taken individually, small concentrations of some spray residues or rot metabolites may not impact either yeast or bacterial fermentation, but collectively they may.

Some important late season vineyard sprays include the following:

- Potassium bicarbonate (Kaligreen, Armicarb, Milstop)

- Monopotassium phosphate (Nutrol)

- Hydrogen peroxide (Oxidate)

- JMS Stylet Oil

- Phosphoric acid products

- Strobilurins

- Sterol inhibitors

- Sulfur

- Copper

3. Copper. Late season copper sprays are considered by most growers to be fairly safe. But is that true? The answer, so often the case with complex systems is, it depends.

A main problem associated with late season copper sprays is linked to the fact that copper is a very strong oxidant. Specifically, copper inactivates glutathione – a very strong antioxidant. Glutathione has the following characteristics:

- Polypeptide found in grapes and yeast

- Strong antioxidant

- Protects labile aroma/flavor compounds

- Is easily degraded

- Copper binds and inactivates glutathione

Oxidative degradation results in the loss of aroma/flavor. There are some important steps known to have a positive impact on minimizing oxidation and the loss of aroma/flavor. These include the following:

- No copper

- Clean, rot-free fruit

- Protection from oxidation via sulfur dioxide, ascorbic acid, glutathione, and/or lees storage

Copper inactivates glutathione. The role of glutathione as an oxidative buffer is receiving considerable attention. Glutathione is a polypeptide produced by the grapevine and by yeast at the end of fermentation. It is a strong antioxidant. Some suggest that minimizing the loss of glutathione is the key to white winemaking.

4. Sulfur. Yeasts can utilize elemental sulfur, sulfate, sulfide, sulfite, thiosulfate, and organic sources of sulfur in grape juice. As a product of sulfate reduction, H2S is an intermediate in the biosynthesis of all sulfur-containing compounds. Consequently, the formation of H2S and other sulfur-containing off-odor compounds in wine is related to both sulfur and nitrogen metabolism.

H2S Formation by Yeast During Fermentation

Sulfur (S0)In a series of regulated steps, sulfate is brought into the yeast cell, and reduced to sulfide via two ATP-activation steps. At this point, sulfide is combined enzymatically with nitrogen-containing carbon precursors to ultimately form cysteine and methionine, two important sulfur-containing amino acids that serve as building blocks for proteins. This sulfate reduction sequence is activated to produce sulfide whenever there is a metabolic demand for cysteine and methionine.

Sulfate (SO4-2)

Sulfite (HSO-3) → H2S

Sulfide (S-2)

Organic - S

In the absence of intracellular nitrogen, sulfate or sulfite reduction can continue. However, this results in the production of H2S that is not incorporated into amino acids, but liberated from the cell into the medium. Therefore, a high rate of sustained H2S production can be observed in response to yeast cell nitrogen deficiency.

VSC Odor Defect in Wine Influences. Unfortunately, many of the factors which influence the production of reductive odor defect are not well understood. The following is a partial list.

- Vineyard

- Must nitrogen, sulfate, organic S

- Micronutrients

- O2 management

- Use of enzymes

- Juice turbidity

- Yeast species and strain(s)

- Fermentation temperature

- Fermentor size and shape

- Sulfur dioxide/ascorbic acid management

- Lees management

- MLF

- Light

Sulfur sprays. It has been established that the presence of as little as 1 µg/L of elemental sulfur on the fruit at harvest can produce an H2S concentration above the sensory threshold (0.5 µg/L) in wine. Additionally, it is understood that some synthetic pesticides containing chemically-bound sulfur and/or metals can be sources of reductive odor defect.

For a detailed discussion of the factors that influence reductive odor defect in wines, see Enology Notes #113 and the on-line publication Volatile Sulfur Compounds at www.vtwines.info.

5. Viticultural HACCP. Understanding the relationships between vineyard spray programs and wine quality requires an established HACCP (hazard analysis and critical control point) plan. The hazard in our case is the inability to craft fine wines and remain competitive. Viticultural HACCP is a means of assuring quality, through the identification and monitoring of critical control points from vine to glass. This plan should include a written understanding of the interval between spray and harvest for all spray materials. For more information, see Enology Notes # 115.

6. Dragon Wines – The Chinese Wine Industry (continued). In November 2006, I was invited to lecture at two universities (Agricultural Research Station of Guangdong Province in Guangzhou, and at the China Agriculture University in Beijing) and tour Chinese wine regions. The following is a continuation from Enology Notes #126, a review of that visit and the Chinese wine industry.

Winemaking in China is an interesting blend of the ancient, Old World and modern chateau-style wine crafting, often at the same facility. Naturally, with a diverse industry, there is a large variation in production practices. The important feature for most Chinese wineries is to keep production costs down for standard volume wines.

Most of the higher-end products are the result of either joint ventures (which may mean simply a consultant on economic linkage) with Europeans or South Americans, or French production practices and philosophy. The majority of the processing equipment I observed was French, with premium wine production rather minimalistic.

I received a broad response to my questions regarding yeast additions: some do, but most suggested they do not add yeast. Sulfur dioxide was the only common addition product. Virtually every winemaker harvests based on sugar; measures of TA, pH, and aroma evaluation are neither common nor of common concern.

Fermentations are conducted in modern stainless steel, concrete, French 200-L barrels or, in some cases, very old wooden (oak) fermentors, with or without temperature control. Red wine cap management is not a large concern and consists almost entirely of pump over. Practices such as cold soak, bleeding, and délestage are not practiced, and none of the producers I visited used extended maceration.

Great Wall Winery is typical. They ferment their premium reds to dryness, rack into Allier barrels for 12 months, and bottle age for one year prior to release. White wine production is made by crush and press (sometimes in screw-type), usually settled, not always with refrigeration, without fining agents, racked, and fermented. Traditionally, fermentation did not occur in oak, but some Chardonnay producers are using oak fermentations.

The bigger wineries, as expected, have high-speed, modern bottling lines. However, virtually every winery uses low-grade corks, often agglomerated, even for their premium wines. As a result, shelf life is limited, which does not seem to be a large concern.

Established Chinese wineries, such as Changyu, Great Wall, and Dynasty, have found a home for their mid-level wines, principally in the eastern modern cities of China and the Chinese towns of the world. They hope to expand beyond those limited markets, certainly in the West. Currently, quality and packaging are both constraints for sales in the West.

Dry wines have overtaken sweet and semi-sweet wine production in the past 12 years. Sales of still red wines represent about 70 percent of the total, which seemed odd, since I do not associate Chinese food with red wines. However, as I learned, food and wine pairing, while starting to catch on in the more affluent eastern cities, is not part of Chinese culture.

Red color represents happiness, good luck, strength, and power, while white is the color of death in Chinese culture. This, coupled with interest in health, may suggest reasons for the trend towards more red wine produced than white. Additionally, red wine and health is promoted by the government, and Chinese society is very interested in the relationships between food and health.

White wines are becoming popular in the cities of southern China, perhaps because of the abundance of fresh seafood in the regional diet. Traditional white wines made from Dragon’s Eye without the aid of modern technology, including refrigeration, have not always been that noble. Premium wineries are changing that pattern, and many have planted Chardonnay.

China can be considered both a western wine marketer’s dream and nightmare. Wine consumption is rising faster than domestic production, currently allowing imports to make up the balance. Beginning January 1, 2004, Chinese tariffs on wine have fallen from 44.5% to 14%. This dramatic reform was brought on as part of China’s accession to the WTO, and has substantially changed the domestic wine market.

Given the traditionally low incomes, the majority of wines must be sold at low prices, a problem in light of the fact that taxes account for about 50% of the retail price of imported wine. Domestic wine can sell for about 20 RMB/L, or about $4 equivalent, with the very expensive about $20.

The government estimates that within eight years, China’s population will be 1.4 billion, increasing at approximately 14 million per year. This represents a lot of potential wine drinkers. The Chinese do drink alcohol, but not much wine (per capita consumption is about 0.2L, vs. 80L for the Italians, for example). With the country’s growing affluence, trend of eating out, and some trends towards Western-type foods, increasing wine consumption will occur. The question is, by how much?

7. Congratulations to Emily Hodson Pelton. Enology-Grape Chemistry Group graduate Emily Hodson Pelton has just won both the Sweepstakes Award for Dessert Wines, and the Judges’ Choice Award (overall winner of the Red, White, Sparkling, and Dessert wine categories), in the Women Winemaker’s Challenge portion of the 2007 National Women’s Wine Competition (www.nwwc.info). Over 1800 wines from 523 wineries in 31 states were judged in the Santa Rosa, California competition. Emily won for her 2005 Kenmar Traminette dessert wine. Emily has been the winemaker at Veritas Vineyard & Winery (www.veritaswines.com) since her graduation with a Master of Science degree from our program.![]()

Subscription to Enology Notes. All past Enology Notes newsjournals are posted on the Enology-Grape Chemistry Group's web site at: http://www.vtwines.info/.

To be added to (or removed from) the Enology Notes listserve send an email message to with the word "ADD" or "REMOVE" in the subject line.

Dr. Bruce

Zoecklein

Professor and Enology Specialist Head Enology-Grape Chemistry Group

Department of Food Science and Technology, Virginia Tech

Blacksburg VA 24061

Enology-Grape Chemistry Group Web address: http://www.vtwines.info/

Phone: (540) 231-5325

Fax: (540) 231-9293

Cell phone: 540-998-9025

Email: