Research Conducted by the Enology-Grape Chemistry Group

Bruce Zoecklein, Department of Food Science and Technology, Virginia Tech

Presented at the Summer meeting of the Virginia Vineyards Association August 2000

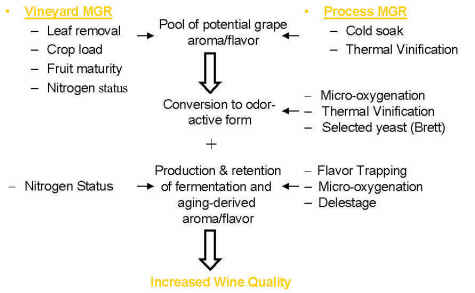

I would like to thank the Virginia Vineyards Association and Dr. Wolf for the kind invitation to be part of todays program. As some of you know, my research efforts involve aroma and flavor. As such, the Enology-Grape Chemistry Group is involved in several on-going projects which are partially outlined in Figure 1.

|

FIGURE 1

My goal today is to provide you with an overview of our activities and a snap shot of a few of these projects which may be of interest to a grower oriented audience.

The Enology-Grape Chemistry Group is involved in three aspects of aroma /flavor research. The first is evaluation of methods for maximizing the production of aroma/flavor precursors in the grape or their extraction into wine. This involves researching the influence of selective leaf removal, crop level, fruit maturity and nitrogen status on aroma and flavor precursors. Studies have been conducted in Winchester, Williamsburg, and California vineyards. Additionally, we have evaluated the influence of cold soak (pre-fermentation maceration) and thermal vinification (use of heat) on the extraction of aroma/flavor precursors.

The second aspect of our research involves conversion of aroma/flavor precursors in the fruit to their odor and flavor active forms. Methods being investigated include microoxygenation (being conducted at Horton Vineyards and involving the addition of a controlled and limited concentration of oxygen into the wine), thermal vinification and the evaluation of selected yeast species and strains.

The third area of aroma/flavor research conducted by our group includes methods to help produce and retain desirable fermentation volatiles (Figure 1). These efforts include flavor trapping (the capture of volatile components produced and lost during fermentation) and Delestage. Delestage is a French process which means rack and return. This processing method involves two features which can improve Virginia red wine structural quality- seed removal and oxidative polymerization of tannin phenols. Research currently in progress at White Hall Vineyards indicates that this process also enhances wine aroma/flavor due to the possible conversion of precursor compounds to their odor active forms.

The nitrogen status of the fruit is another active study. We know that the nitrogen status of the fruit has a major influence of volatiles produced during fermentation. We are currently evaluating a method for vintners to easily determine grape nitrogen status.

One important question that we are attempting to answer is how are vineyard yields and wine quality related. The assumption that they are inversely related is deeply ingrained and yet the question of yield vs quality must be one of the most important issues for the entire global wine community. Cropping level and wine quality have a complex relationship due to many of the interactions listed in Table 1 and lead to the question, "What creates wine quality?"

|

TABLE 1

Most of us know that significant over or under-cropping can influence wine quality. However, where is the break point at which additional crop will negatively impact quality? That is the practical question. As you know, if we crop vines too heavily the crop load can delay the rate of fruit maturity.

|

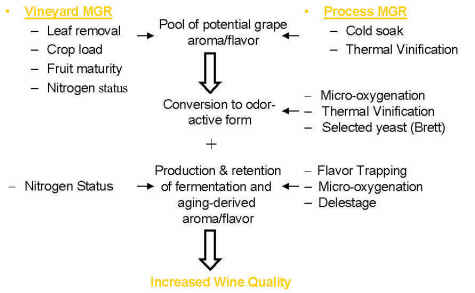

TABLE 2

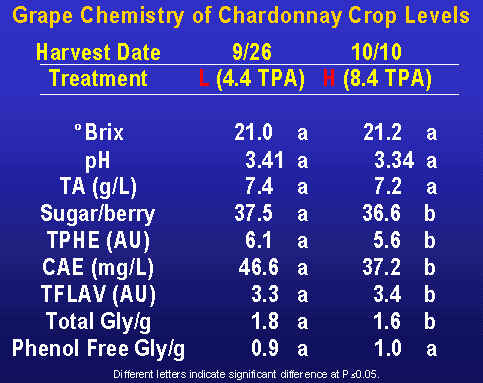

Table 2 illustrates that delay. Chardonnay vines grown on an open lyre system in Winchester were cropped at three levels and harvested on one date. Different letters across indicated significant differences. All other factors equal, this is what you would expect. The lowest cropped vines mature the most rapidly in terms of degrees Brix. At a set harvest date the Brix values are different and follow the logical expected pattern. The pH is about the same among treatments while TA, sugar per berry, total phenols (TPHE), flavonoid phenols (TFLAV) and total glycosides (Total Gly) are higher in the low-cropped, more mature fruit. The total glycoside concentration is an estimation of the total pool of secondary metabolites, some of which are important aroma/flavor precursors. This data is expressed on a gram per fresh fruit weight basis to account for any variation in berry size.

Wine quality, as you might guess, would be different from these three crop levels, and indeed it was. Evaluators could easily differentiate wines produced from the three crop levels. The real question, however, is, "If we simply allow the high crop level grapes to stay on the vine long enough to reach 23.5 degrees Brix will the wine quality be the same, better than or lower than that from the low crop level?" In other words, does crop level simply delay maturity or are there qualitative effects on grape components and subsequent wine quality?

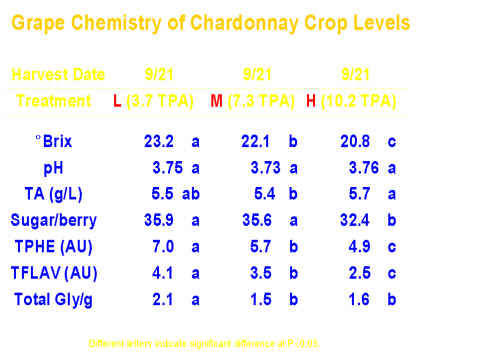

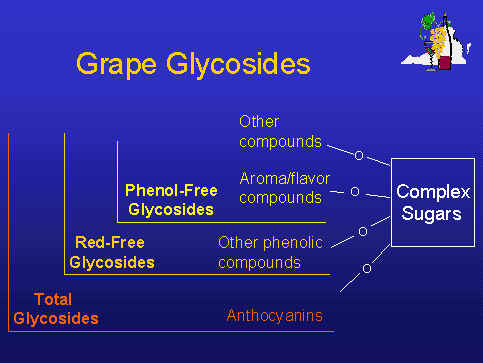

To help to answer these questions we have produced and evaluated wines from different crop levels harvested at the same target Brix values. We have also measured glycosides, important secondary grape metabolites. These secondary metabolites are responsible for wine color, aroma, flavor and structure. Many of you have heard me speak of glycosides before. They represent, in part, the pool of potential aroma/flavor compounds. The Enology-Grape Chemistry Group has been evaluating methods for separation of various types of grape glycosides. Glycoside fractions are depicted in Figure 2. Total glycosides measure the entire pool of secondary metabolites. The quantification of red-free glycosides estimates the concentration of all glycosides with the anthocyanin or pigmented glycosides removed. This is a useful measure when the effects of color must be eliminated. Our group has been evaluating a phenol-free glycoside measure which we believe provides a truer estimation of aroma/flavor across a broad degrees Brix range. Research suggests that the total glycoside concentration is positively correlated to wine quality at high degrees Brix levels (greater than 21.5), while phenol-free glycoside concentration seems to be positively correlated to wine quality over a broader degrees Brix range. Much of our research effort has been on methods of separating types of these compounds. There is a positive correlation between the concentration of total glycosides and wine quality at high Brix levels. We believe such measurements may allow us to model the relationships between crop level and quality.

|

FIGURE 2

If we look again at Table 1 and the glycoside content it can be noted that it is significantly higher in the low cropped vines. If the total glycoside concentration is positively correlated to wine quality, one would expect that if the high crop vines are to produce wine of equal quality to the low crop then the concentration of total glycosides in the high crop should eventually equal that of the low crop vines. Again the question remains, will the high cropped vines produce the same wine quality if we simply hang the fruit longer? The answer seems to be related to the length of time required to reach a targeted Brix value. The longer it takes for the degrees Brix to catch up the less likely it is that the glycoside concentration will catch up and wine quality will be equal.

|

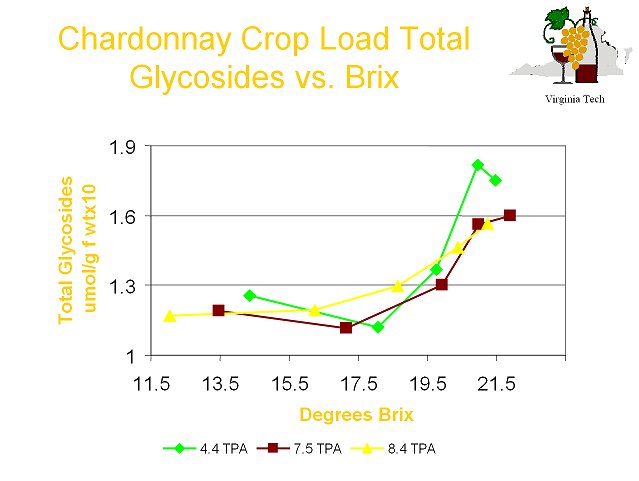

FIGURE 3

Figure 3 shows some data from another imposed crop level treatment, again on Chardonnay grown on an open lyre system in Winchester. Crop levels were equivalent to 4.4, 7.5 and 8.4 tons per acre. This illustrates the change in degrees Brix plotted against total glycoside per gram of fresh fruit weight to account for differences in berry size. This slide is typical of what we have observed.

There are several things to note from Figure 3. At relatively low Brix values (below 19.5) there is not much difference in the glycoside concentration among these three crop level treatments. As previously stated, glycosides are measured on a fresh fruit weight basis to eliminate variations resulting from differences in berry weight. Sensory studies confirmed that there is no difference in the varietal aroma attributes from wines produced from this fruit.

Additionally, within a relatively narrow Brix range (19.5- 21.5) there is a substantial increase in the concentration of glycosides. We call this increase engustment and it is accompanied by substantial increases in the varietal aroma/flavor of the fruit and subsequent wine. This data provides additional justification for the belief that Brix alone, particularly in a warm climate such as Virginia, may not be a completely reliable measure of potential wine quality.

|

TABLE 3

Table 3 shows some of the data from Figure 3 at harvest. In this case, fruit from the three crop level treatments was harvested at a targeted Brix of 21 rather than at a set date. I have removed the mid-level treatment to simply the table. As can be noted, the high crop level reached the target Brix 14 days after the low crop. If we look at the fruit chemistry it doesn't appear to be dramatically different. But there are slight differences in the total glycoside content. No difference in the phenol-free glycosides were noted. As stated, we believe phenol-free glycosides are a better predictor of potential wine quality at lower Brix values.

|

TABLE 4

How about the wine quality? Table 4 shows the results of duo-trio difference testing on wines produced from the fruit of Table 3. Three glasses are presented to evaluators, two the same and one different. They are asked if they could determine which was the different wine. The numbers listed are the correct responses of the total responses. As Table 4 indicates, the judges could not distinguish between aromas of wines produced from these three crop level treatments. Were the glycoside concentration differences great enough to make a sensory difference, particularly in varietal aromas in the wine? No, not if our target Brix was 21. However, what happens if we raise our target degrees Brix?

|

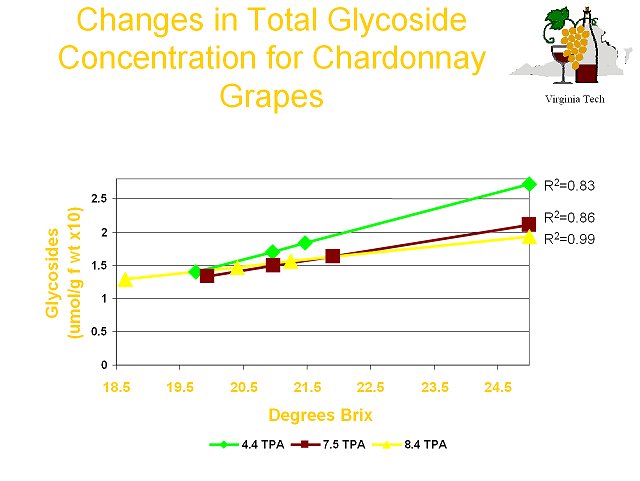

FIGURE 4

Figure 4 shows a regression model from the same study which demonstrates the change in glycoside concentration on a fresh fruit weight basis plotted against degrees Brix. At relatively low Brix values (as noted in Table 3) the differences in grape glycoside concentration among treatments is minimal, as are wine quality differences. However, as we move to higher Brix values the differences in the total glycoside content becomes greater, as do the differences in the aromas/flavor of the wines produced from these treatments.

If our target Brix is raised and we harvest all treatments at that target Brix there is a difference in the wines produced. At a high target Brix the glycoside concentration of the higher crop level grapes in this model never catches up to the low crop vines. This is typical. The spread in glycoside concentration and resultant wine quality is greater the longer the grapes hang on the vine, all other factors being equal.

From these studies a few generalizations can be made for a particular cultivar:

1. The time to reach a targeted Brix value is positively correlated to yield. In other words, the greater the yield the longer the time it takes to reach a certain degrees Brix.

2. Total glycoside concentration is positively correlated with Brix and wine quality only at high degrees Brix values(>20.5).

3. Over the wide range of sugar concentrations, phenol-free glycoside concentration is positively correlated with Brix and wine quality.

4. Total and Phenol-free glycoside concentrations and wine quality are negatively correlated with the time it takes to reach a targeted Brix, notably at Brix values greater than 20.5.

Given the above, why can't we simply provide growers with some formulae recommendation regarding yield and quality? It is not simply yield that influences ripening. Ripening is also influenced by a host of other factors including solar exposure of the fruit.

|

FIGURE 5

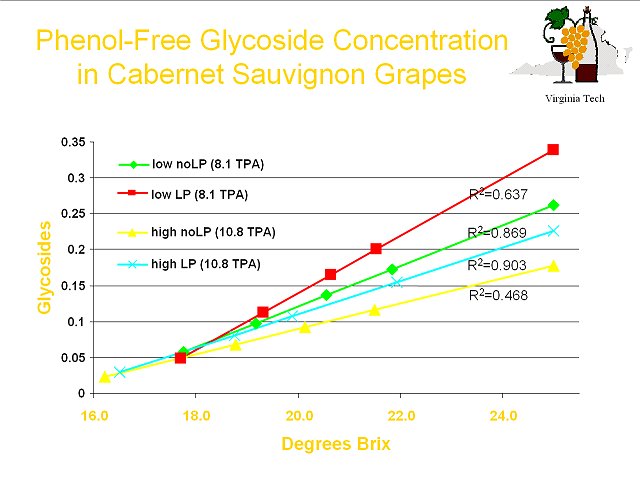

For example, Figure 5 shows the relationship between degrees Brix and phenol-free glycoside concentration of two Cabernet Sauvignon crop levels where fruit zone leaf removal also was imposed. Again, the phenol-free glycosides subtract the influence of color and other phenols.

The data depicted in Figure 5 follows a predicted pattern. The highest concentration of phenol-free glycosides was found in the low cropped, leaf-pulled vines followed by the low crop non-leaf pull. In this study, the glycoside concentration was influenced by both crop level and leaf removal. The differences among crop level treatments becomes greater at higher Brix values. At relatively low degrees Brix concentrations the differences in phenol-free glycosides were minimal as were the differences in wine quality. As we move to the right on Figure 6 (increase our targeted Brix) the differences in glycosides and wine quality become much greater.

|

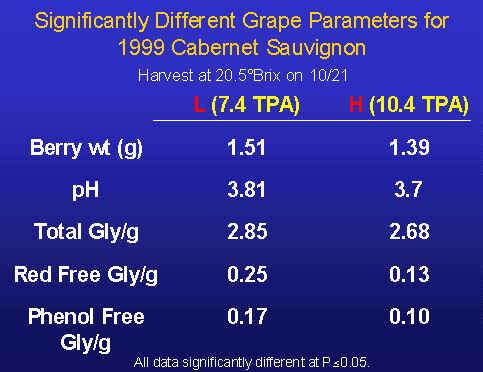

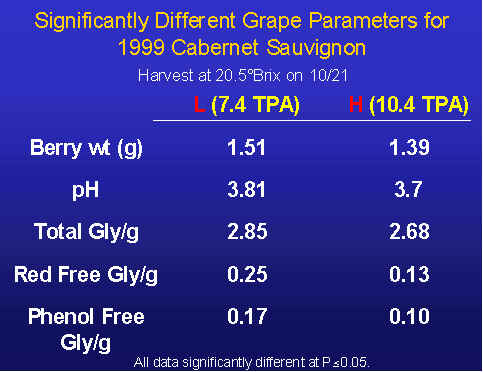

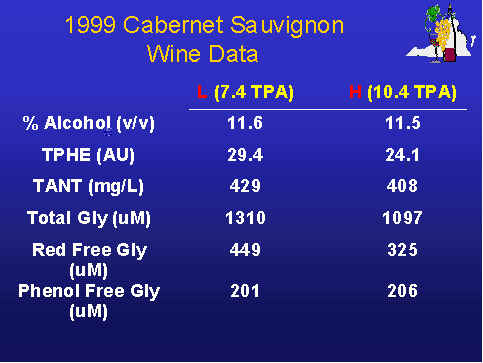

TABLE 5

We have observed differences in wine quality even when there are no apparent differences in the rate of fruit maturity as measured by degrees Brix. Table 5 shows only the significantly different grape parameter data of Cabernet Sauvignon fruit grown on a divided canopy at two crop levels and harvested at one date. There was no statistically significant difference in Brix, yet slight differences in fruit chemistry. Table 6 shows the chemistry of wines produced. As can be noted, there were slight differences in the alcohol concentration (and therefore, slight differences in

|

TABLE 6

Brix values) which could have provided a confounding influence. Both the total and phenol-free glycoside concentrations were influenced either by crop level treatment and/or by the very minor differences in the degrees Brix of the fruit. Sensory analysis of this wine demonstrated perceptible differences among the wines. These data indicate the importance of adequate maturity evaluation and the relationship to wine quality.

The relationships between yield and quality are complex due to the factors listed in Table 1. There may be no exact point when overcropping begins. The issue of crop level and wine quality for now comes down to a question of vine balance, balance of yield and vegetative growth and balance of economic considerations. Naturally, from a winery view there is no benefit to having twice the fruit at half the quality. Growers must work carefully with wineries to assure that the interests of both parties are considered and to help the Virginia grape and wine industry maximize it's full and complete potential.

Delestage

A second study which involves grape grower is currently being conducted at White Hall Vineyards, one of the stops on to days tour. Delestage is a french system know as rack and return. While this is a winery process it stems, in part, from some viticultural concerns.

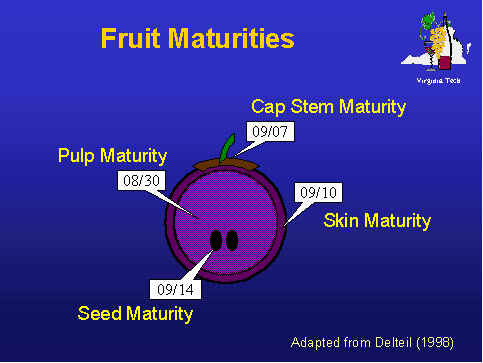

Maturity evaluation is a very important feature relative to potential wine quality. It is difficult due to a number of factors non the least of which is that the grape is not a homogenous entity. That is, it is composed of several parts, each of which ripen at different rates. For example, a berry consists of the important components of skins, pulp, seed and cap stem. In red wine production all of these are entering the fermenter (Figure 7). Therefore, if one or more of the component parts is not physcolically ripe or mature, that may negatively impact wine quality.

|

FIGURE 7

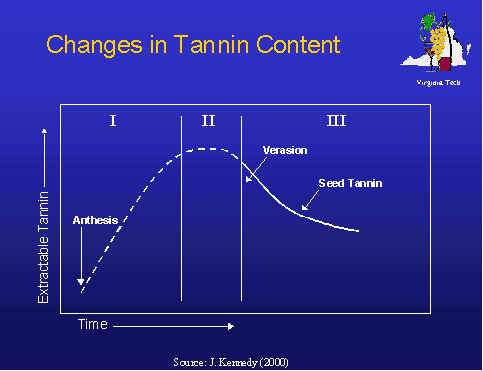

In Virginia we frequently process red grapes which have immature skin or notably seed tannins. As Figure 8 indicates, during fruit maturation the seed tannins mature. The maturation of seeds does t not necessarily occur at the same rate of degrees Brix increases. As seed mature they change color from green to light brown then dark brown. This change represents an oxidative reactions. The result is that the tannins are less easily extracted into the fermenting red wine. Frequently we have adequate Brix but not adequate seed maturity. Winemaker can do little at the winery if the fruit has immature skin or seed tannins. The end result is that the red wines with immature skin or seed tannins are harsh and hard

|

FIGURE 8

In most conventionally produced red wines, seed tannins make up over 60% of the total tannins in the finished product. That is not good news if the fruit has a high concentration of immature seeds.

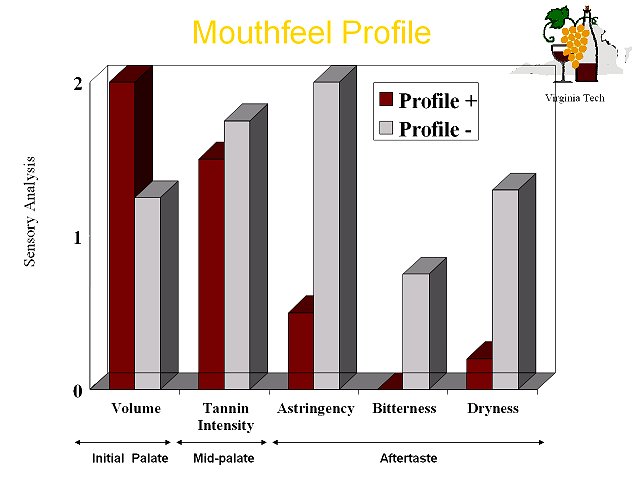

What does this mean with regard to red wine profiles? As Figure 9 demonstrates immature seeds add to the negative profile, specifically, an increase in astringency, bitterness and what we call dry-dusty like tannins.

|

FIGURE 9

Delestage, a rack and return red wine production method, has two important red wine quality features, partical seed removal and oxidative polymerization. The ability to remove up to 40% of the seeds allows for the production of supple red wines which follow the positive profile depicted in Figure 9.