Enology Notes

Enology Notes #117, August 30, 2006

To: Regional Wine Producers

From: Bruce Zoecklein, Head, Enology-Grape Chemistry Group, Virginia Tech

Subject: Tannins, Color and the 2006 Season, continued: Phenolic Compounds and Red Wine Processing

Tannins, Color and the 2006 Season, continued: Phenolic Compounds and Red Wine Processing. The following is a continuation from Enology Notes #116. The concentration of phenols in red wines is dependent on the grape and vinification factors. Generally, no more than 50% of the total phenols present in the skins, seeds, and flesh of grapes can be extracted during conventional winemaking.

Processing features listed in Figure 1 can impact the phenolic concentration of the resultant wine.

Figure 1

The extraction rate of phenols during processing is primarily a function of the following:

- maturity of the phenolic elements in the skins, seeds, pulp, and stems (including cap stems)

- temperature

- contact time

- alcohol content at dejuicing

The main effects from winemaking techniques are galloylation, the association with seed tannins. Increased galloylation can increase astringency.

We know that prefermentation sorting is important with regard to phenolic composition of wines, as is gentle fruit handling. Gentle handling is reported to be one of the benefits of gravity flow processing, as a result of minimizing the extraction of phenols, by limiting the non-soluble solids extraction.

An area traditionally overlooked is post-destemming sorting to remove cap stems or jacks. Stem tannins are chemically different from skin tannins, and impart a different sensory profile. Stem tannins, including cap stem tannins, are more astringent and harsher than skin tannins. Jack stems in the fermentor can be a problem, if the concentration is high and the stems are green or not lignified, resulting in increased tannin intensity and astringency.

Various cap management protocols such as punch down, pump over, etc., have an impact on the following:

- non-soluble solids concentration

- rate of phenolic extraction

- DP number (degree of polymerization, see Enology Notes #116)

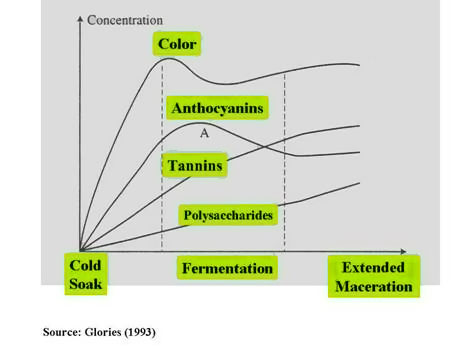

Figure 2

Figure 2 shows hypothetical curves, illustrating the relative changes in spectral color, anthocyanins, total tannins, and polysaccharides, from cold soak, through extended or postfermentation maceration. Extraction of individual classes of phenolic compounds differs during processing.

Cold Soak. An important initial processing question is the desirability of cold soak, or prefermentation maceration. The rationale behind cold soak is that aqueous extraction in an non-alcoholic matrix improves wine color and color stability, and may increase aromatic intensity. Is that true? Sometimes, yes, but not always.

Monomeric anthocyanins are extracted during cold soaking, which may result in increased finished red wine color (Figure 2).

Tannin extraction during cold soak is limited by solubility. As can be noted from Figure 2, tannins are extracted at a slightly lower rate than anthocyanins, but the extraction continues throughout the maceration period. Seed tannin extraction requires ethanol. Therefore, tannins extracted during cold soak are from the skins and stems, not the seeds.

Important cold soak variables include the following:

- varietal

- season

- time

- temperature

Varieties like Pinot noir may actually have less red wine color following cold soak. Highly-colored varieties, like Cabernet Sauvignon, frequently demonstrate an increase in color absorbance at 520nm as a result of cold soak, but this increase may not persist through wine aging. The impact of cold soak on various varieties needs further review.

Large variations, mainly in cofactor concentration (see Enology Notes #116), may be responsible for both varietal and seasonal variations on the impact of cold soak.

Most winemakers practicing cold soak use a temperature low enough to limit the growth of unwanted microorganisms, such as Kloeckera. As such, a temperature below 10°C is considered desirable.

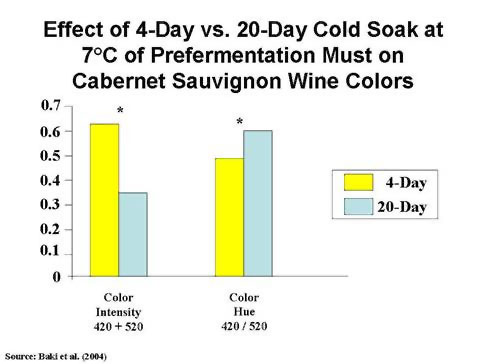

The duration of cold soak varies considerably. During a trip to Chile in 2004, I visited with winemakers who suggested the desirability of a 20-day cold soak. A student in the Enology-Grape Chemistry Group examined the impact of cold soak time on Cabernet Sauvignon wine chemistry, seven months post-fermentation (Figure 3 and 4). NS indicates not significant, * indicates significance at 0.05.

Figure 3 and 4

Red-colored pigments have a maximum absorption at 520nm. Brown pigments have a maximum absorption at 420nm. Color intensity (520 nm + 420 nm) actually decreased with increased cold soaking time. Color hue, defined as the ratio of these two wavelengths, went up, likely due to the increased relative concentration of tannins, which contribute to brown color.

Practical effects of cold soak are a function of time and cultivar. There may be little benefit from more than three days soaking. The impact of cold soak on wine aroma has not been fully resolved.

Cap Management. How the cap is managed impacts the rate of extraction of phenolic compounds. Mechanical punch down, pump over and, in particular, rotation methods, can significantly increase the rate of extraction and the extent of phenolic polymerization.

For the first five to seven days of fermentation, extraction comes predominantly from the skins and stems (Figure 2). Thereafter, the seed coat cuticle is dissolved by the ethanol, and extraction from seeds predominates. From this point on, increases in tannin concentration are mainly from the seeds. This highlights the importance of seed tannin maturity.

Free anthocyanins begin to decline when alcohol concentration reaches a certain level (Figure 2). It is at this point that anthocyanins begin to be incorporated into tannins to form polymers. Generally, the DP of the phenols increases with fermentation.

Polysaccharides are mainly extracted from the grape at the beginning of the vatting period (Figure 2). High polysaccharide-producing yeasts have become important winemaking tools. Such yeasts can modify the wine palate profile, notably by lowering the perception of the phenolic and acidic elements (see Enology Notes #81).

Color rises during cold soak, as the development of copigmentation and polymerization continues. Color intensity will reach a maximum, then decline (Figure 2). This represents extraction from the fruit and binding of anthocyanin with tannins, to form small and large polymeric pigments that are red-brown.

Maceration Variables. Important maceration variables include:

- duration - impacts the percentage of phenols from the seeds

- temperature - impacts the rate of extraction from the skins, stems, and seeds

For example, increasing the temperature from 15°C to 35°C increases the rate of extraction, and may increase the concentration of total phenolic compounds by as much as 200%.

Sulfur Dioxide. What is the effect of sulfur dioxide on phenolic extraction and color formation? Sulfur dioxide mainly binds to sugars, but can bind phenols at the carbon-4 position of the flavonoid phenol. As such, too much sulfur dioxide can have a negative impact on phenolic polymerization.

Sulfur dioxide generally has little impact on the extraction of phenols from the fruit. Sulfur dioxide may be of benefit in helping to minimize the extent of oxidative degradation of color cofactors.

Maceration Time. What is the impact of maceration time on phenols? Longer maceration during fermentation can increase both the anthocyanin and the tannin content in the wine. As such, there is a big difference between 4-5 days and 10-days fermentation, in the percentage of polymeric pigments after the wine has aged for one year. The greater concentration of polymeric pigments occurs with the slower fermentation.

Extended, or postfermentation, maceration does not increase the anthocyanin content, but does increase the concentration of tannins (Figure 2). The increase in tannins is from the skins, and notably from the seeds. This is usually accompanied by increased phenolic polymerization rates, and may result in wines that have a softer mouthfeel.

An often-asked practical question is, what is the optimum time period for extended maceration? The answer relates to vineyard uniformity, fruit chemistry, and stylistic goals. During extended maceration, both extraction from the skin and seeds, and polymerization, are occurring. Some choose to monitor these changes by sensorially comparing a top sample with a bottom sample. Bottom samples, due to the proximity of the seed load, will have relatively high seed tannin concentrations. There are usually limited changes within the first 6-10 days postfermentation. Wines with this extent of maceration are often hard and harsh. Afterward, polymerization, and the possible association of phenols with other compounds, aids in suppleness.

Pectic Enzymes. The effect of pectic and maceration enzymes depends on a number of factors, including cultivar, maturity, the specific enzyme used, and the alcohol at dejuicing. It also depends on when you dejuice, as to how significant enzymes may be.

Generally, pectic enzymes impact tannin extraction more than anthocyanin extraction, due to the fact that tannins are not as soluble. Therefore, the use of pectinolytic enzymes can change the ratio of anthocyanins to tannins. Pectinolytic enzymes may be an important wine processing tool, particularly in the case of short vatting.

Pectinolytic enzymes can impact the following:

- increased extraction of color, notably if you are short vatting

- increased extraction of tannins

- increased rate of polymerization

There are a number of enzyme preparations available for different winemaking functions.

More to follow.

![]()

Subscription to Enology Notes. All past Enology Notes newsjournals are posted on the Enology-Grape Chemistry Group's web site at: http://www.vtwines.info/.

To be added to (or removed from) the Enology Notes listserve send an email message to with the word "ADD" or "REMOVE" in the subject line.

Dr. Bruce

Zoecklein

Professor and Enology Specialist Head Enology-Grape Chemistry Group

Department of Food Science and Technology, Virginia Tech

Blacksburg VA 24061

Enology-Grape Chemistry Group Web address: http://www.vtwines.info/

Phone: (540) 231-5325

Fax: (540) 231-9293

Cell phone: 540-998-9025

Email: